Knowing how fast the spindle is turning is critical for any CNC machining operation, and after many years of struggling I was long overdue for a more robust tachometer solution. Shining the laser of a handheld tachometer through the enclosure window was always an annoying task, and the accuracy was often questionable with chips flying in the path of the laser.

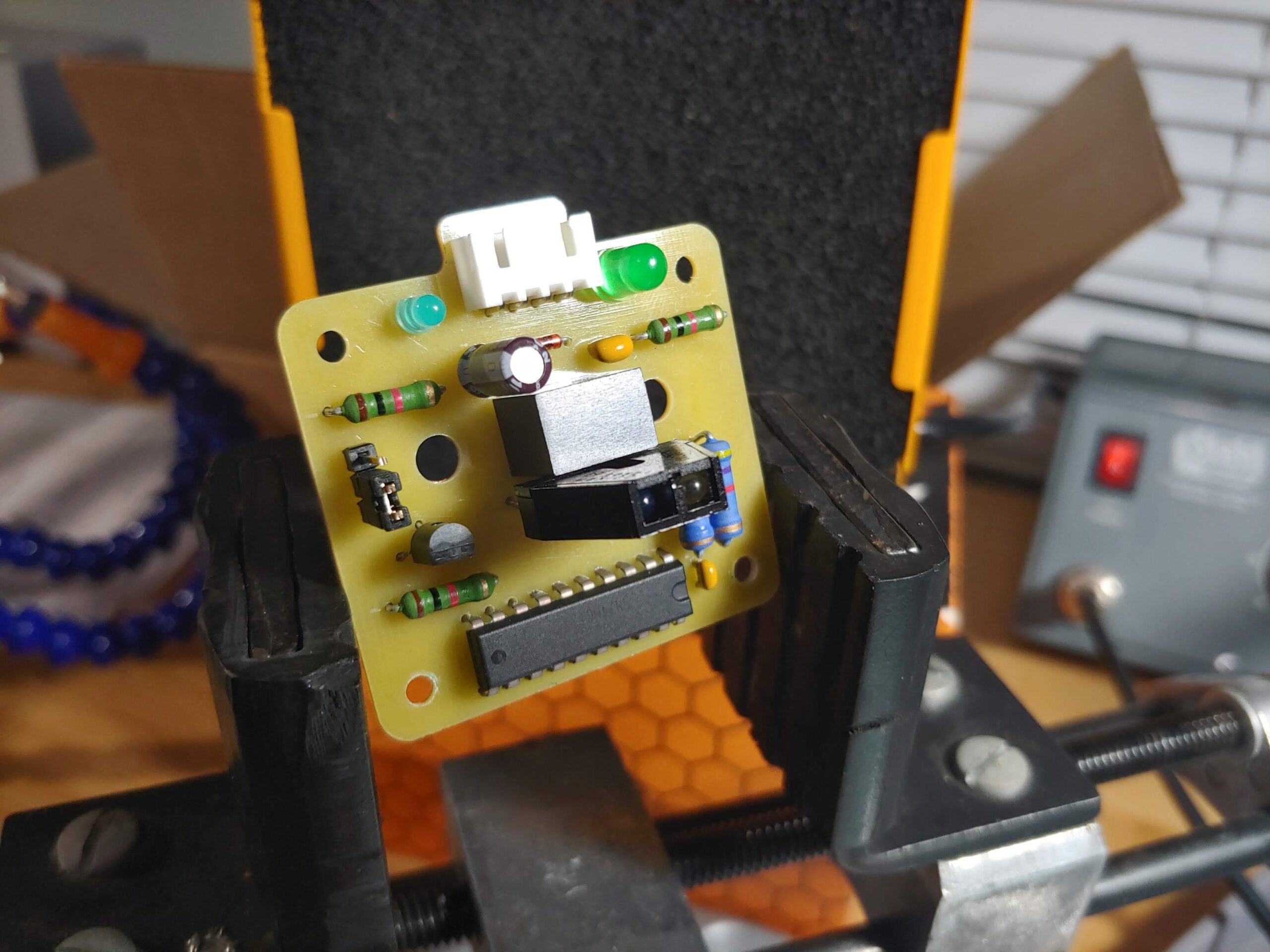

Fortunately, a member of the CNCZone forums posted an excellent design for a tachometer for my Taig mill. All I had to do was modify the circuit slightly to accept a 48V power input from my mill power supply, rather than the 12V the circuit was designed for. Squeezing a 48V regulator onto the circuit board large enough to run the LEDs proved to be challenging, but there was just enough space to fit all the upgraded components without increasing the board size.

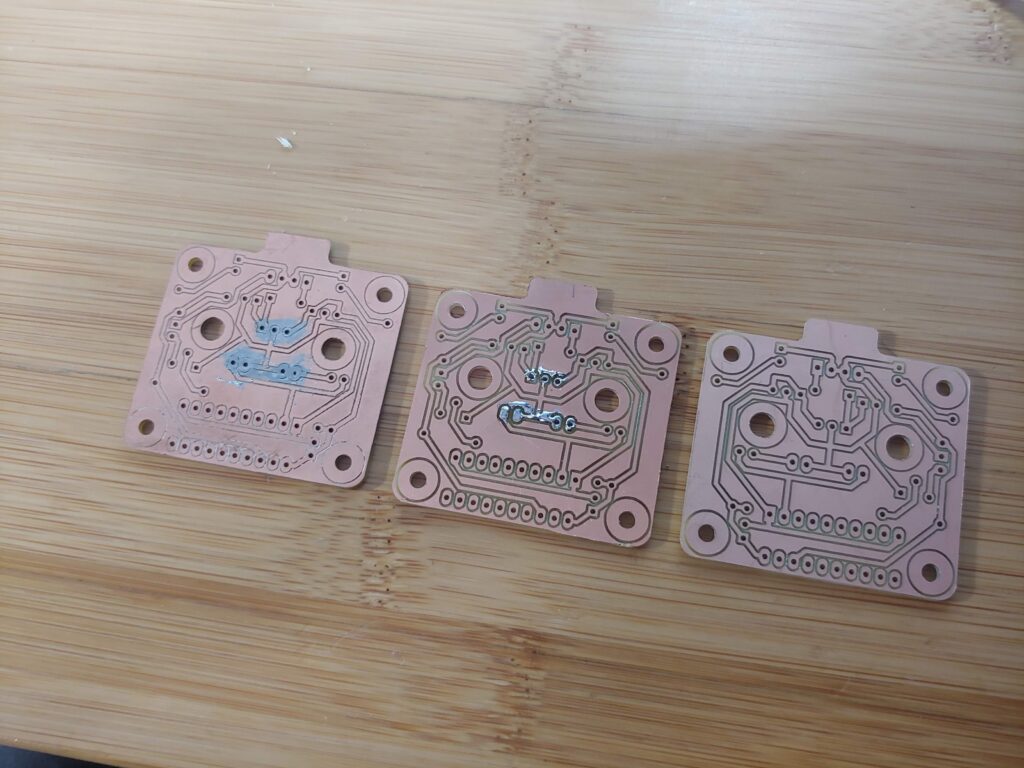

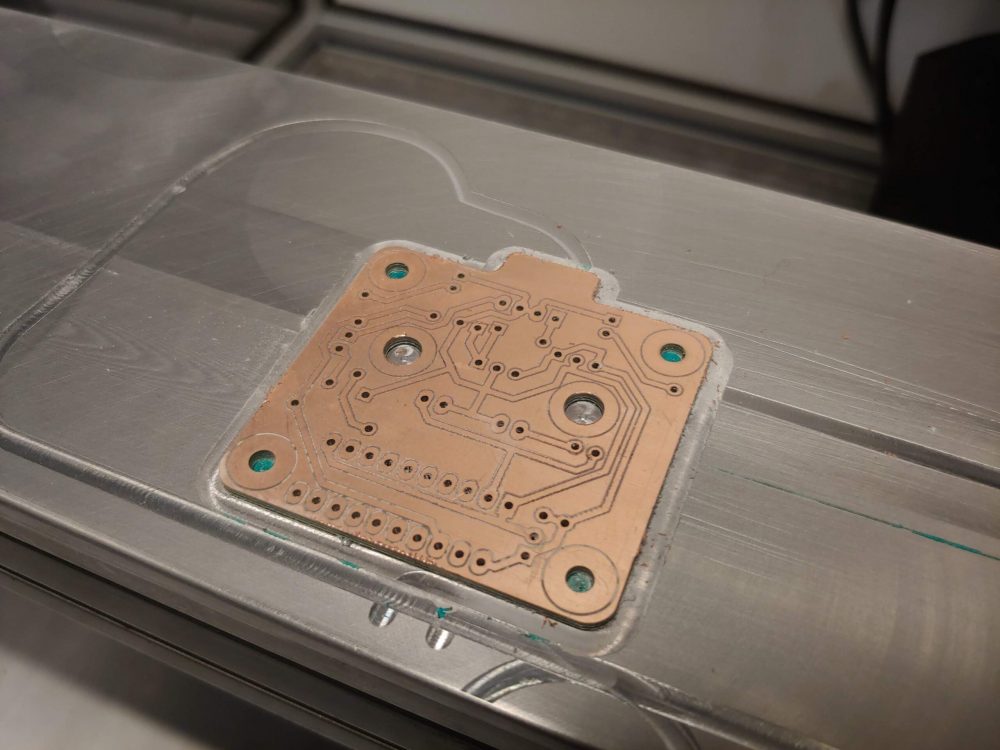

This was my first attempt at circuit design and circuit board milling, but the board came out great. Getting the board right took a few tries, but with the RPM now reading out directly into the mill control software I can happily say my days of cursing a harbor freight tachometer are over.