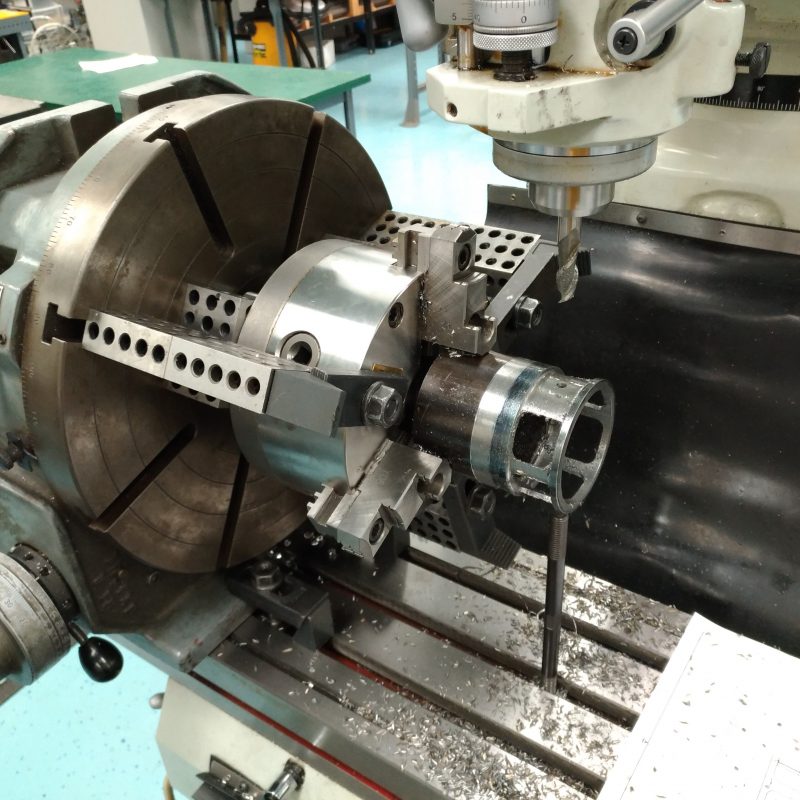

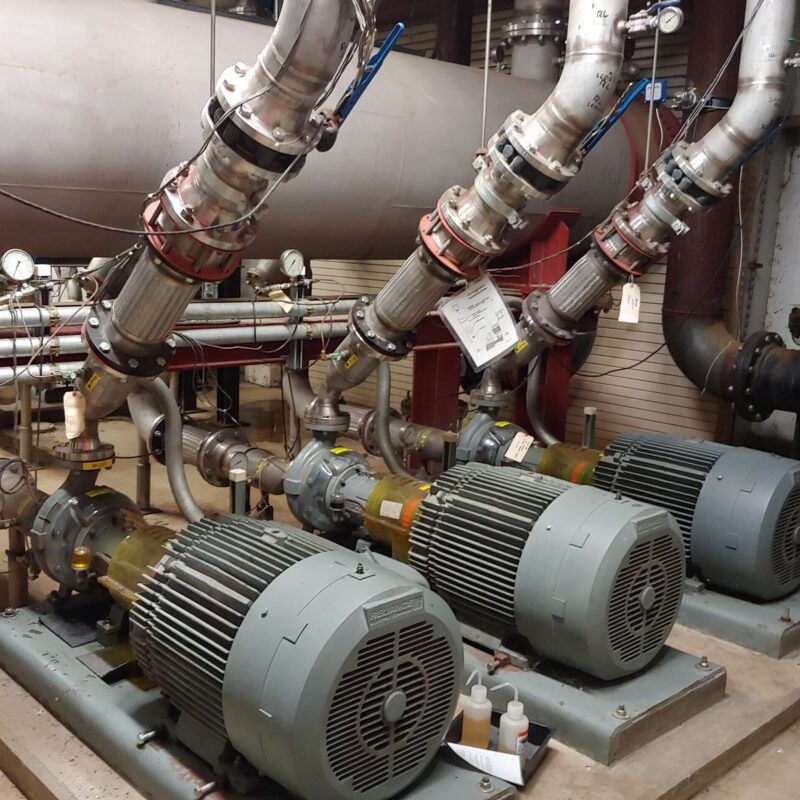

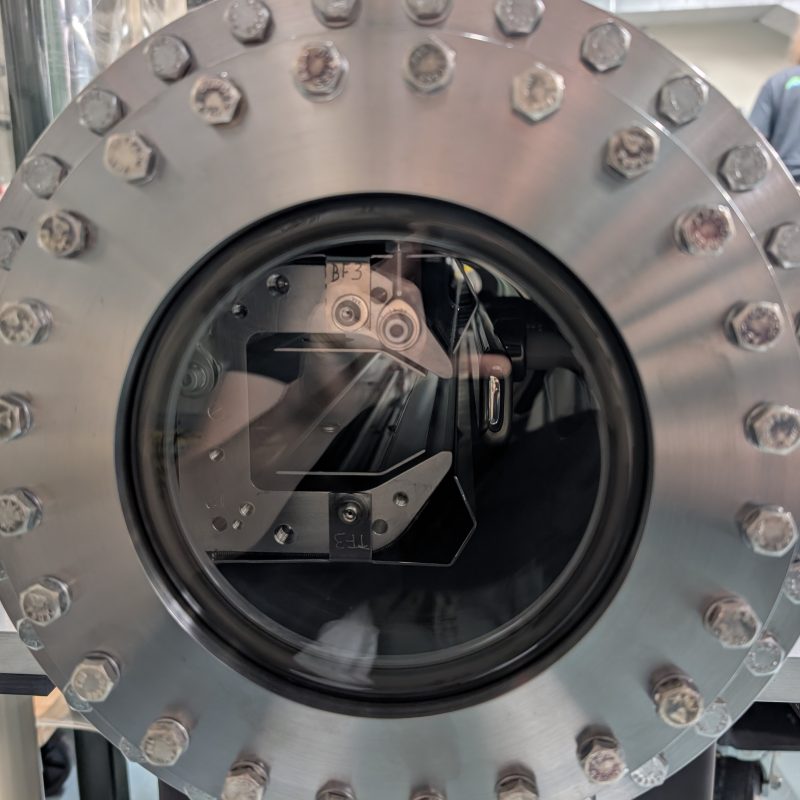

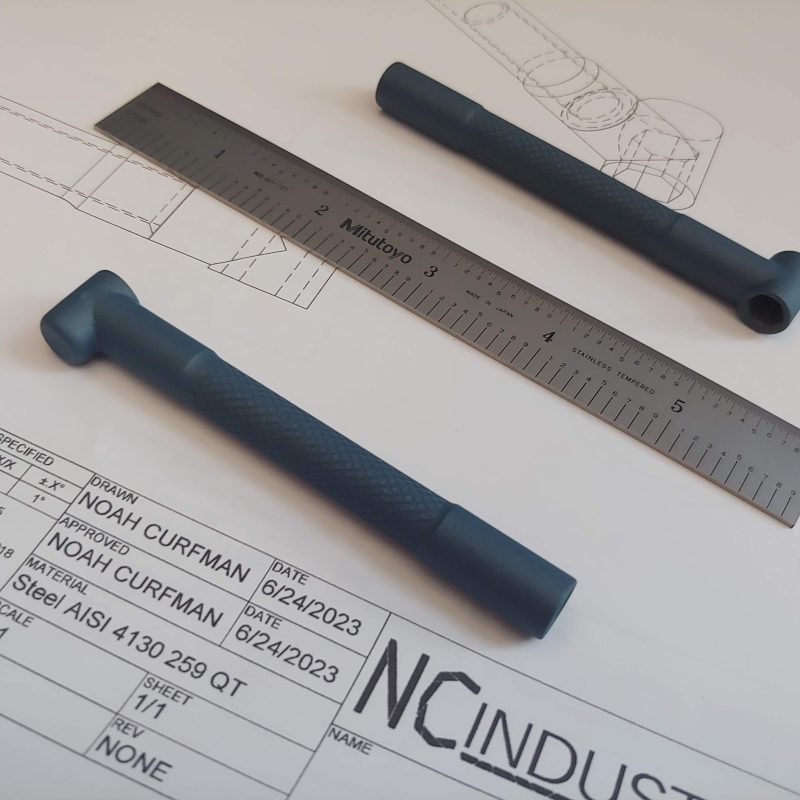

Professional Projects

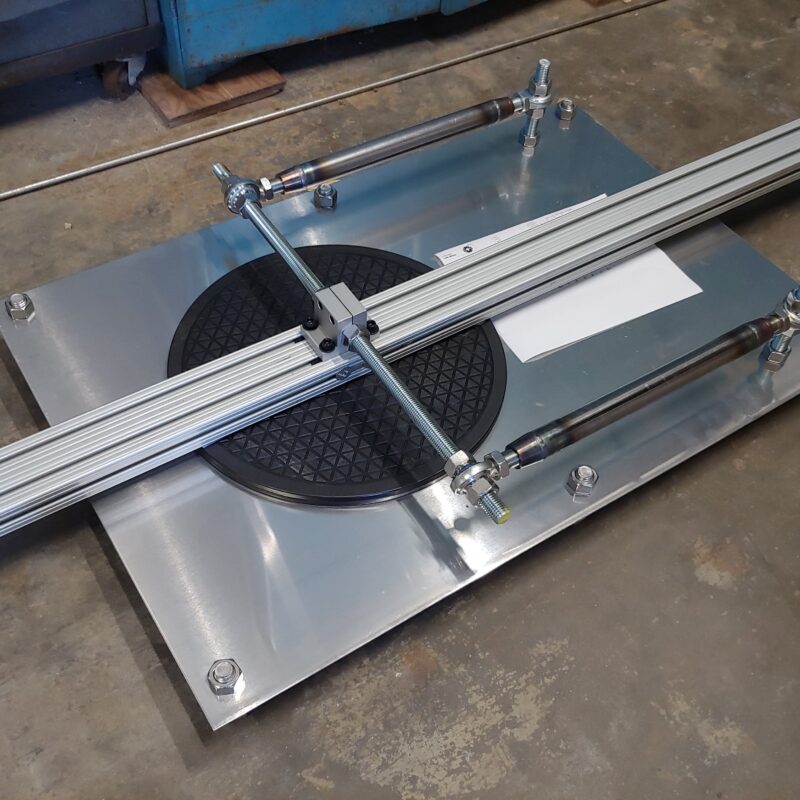

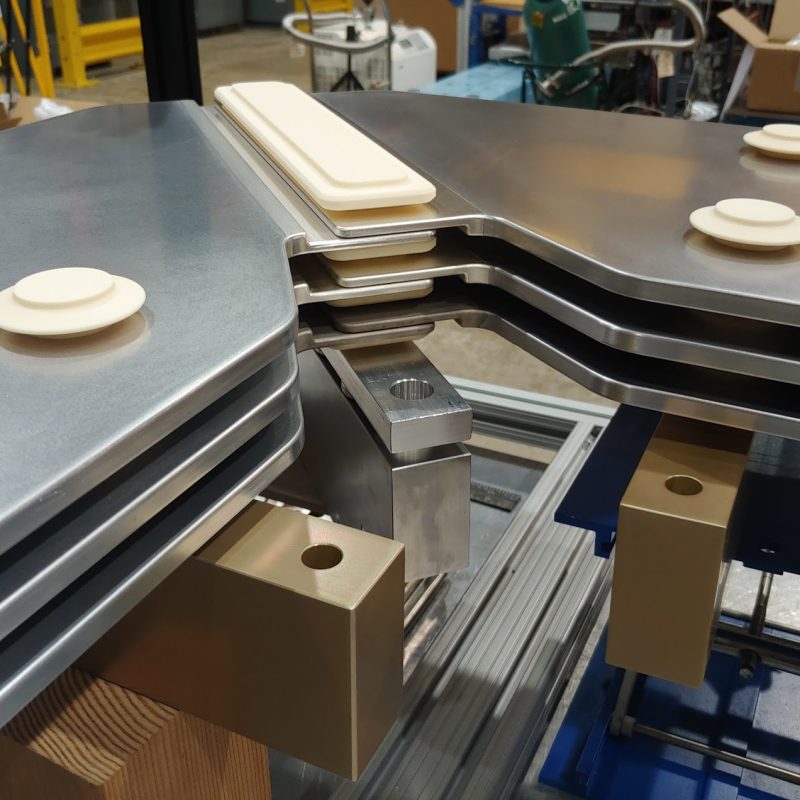

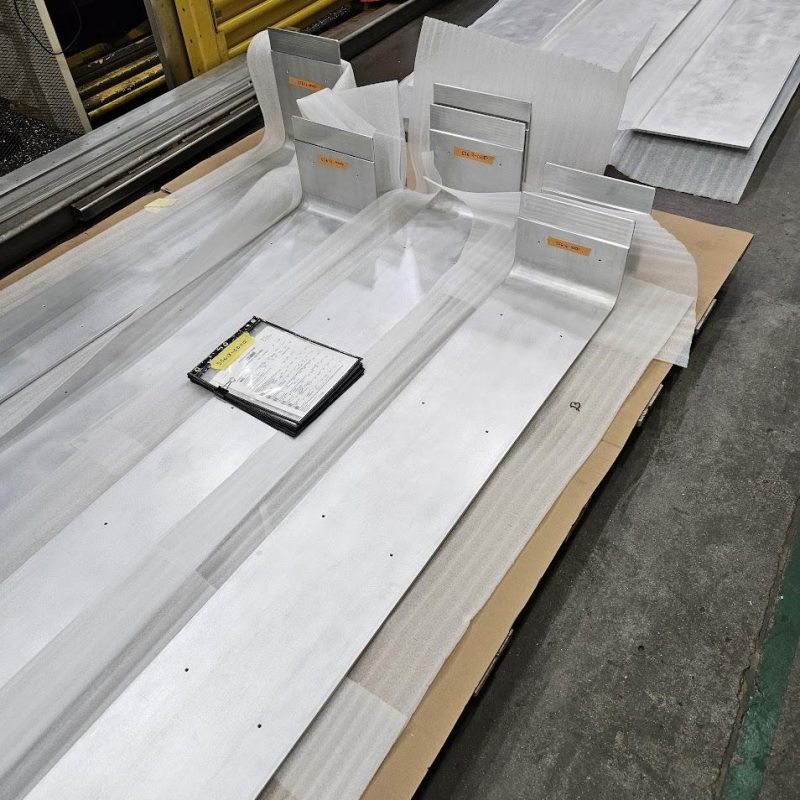

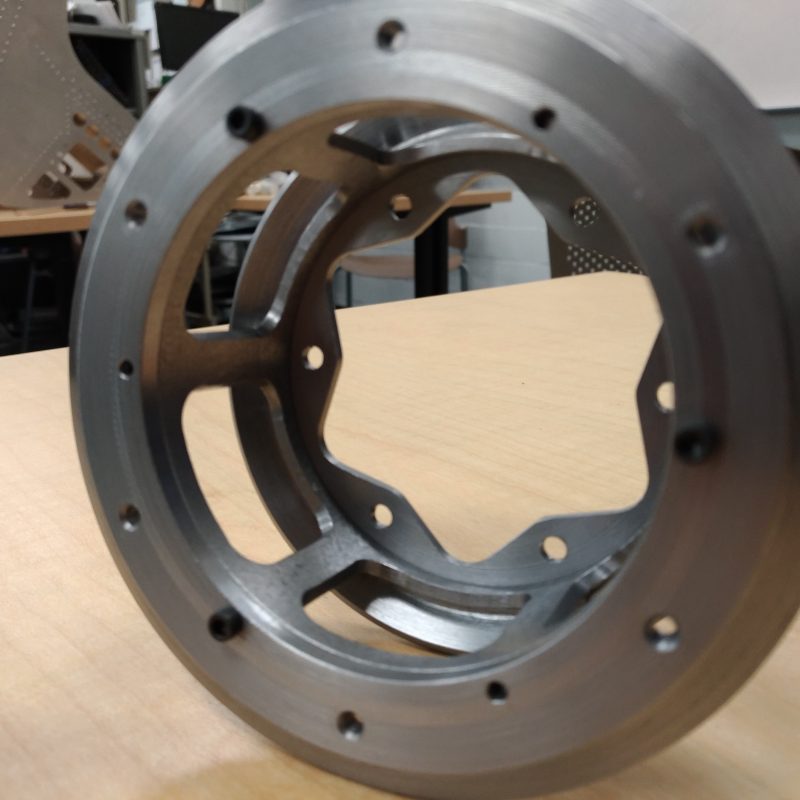

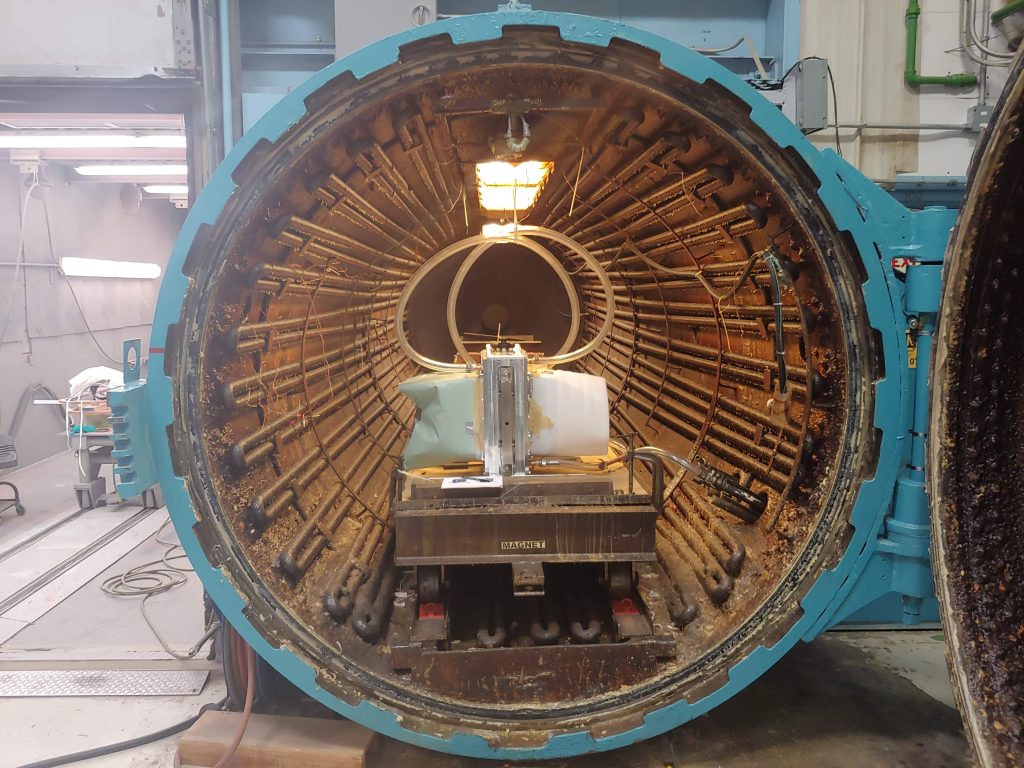

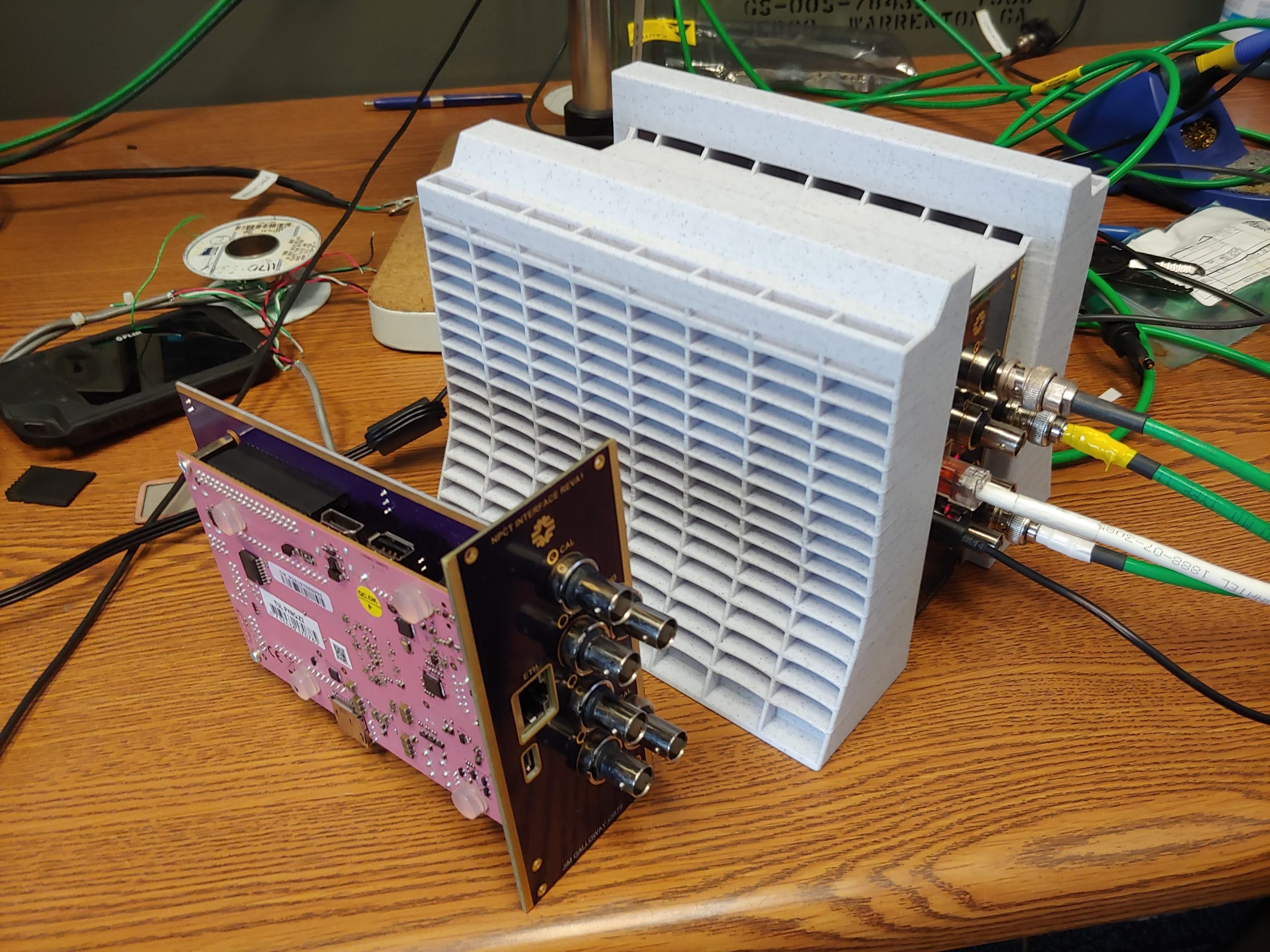

Click to learn more about the exciting projects I work on at Fermilab, and how I've approached engineering challenges.

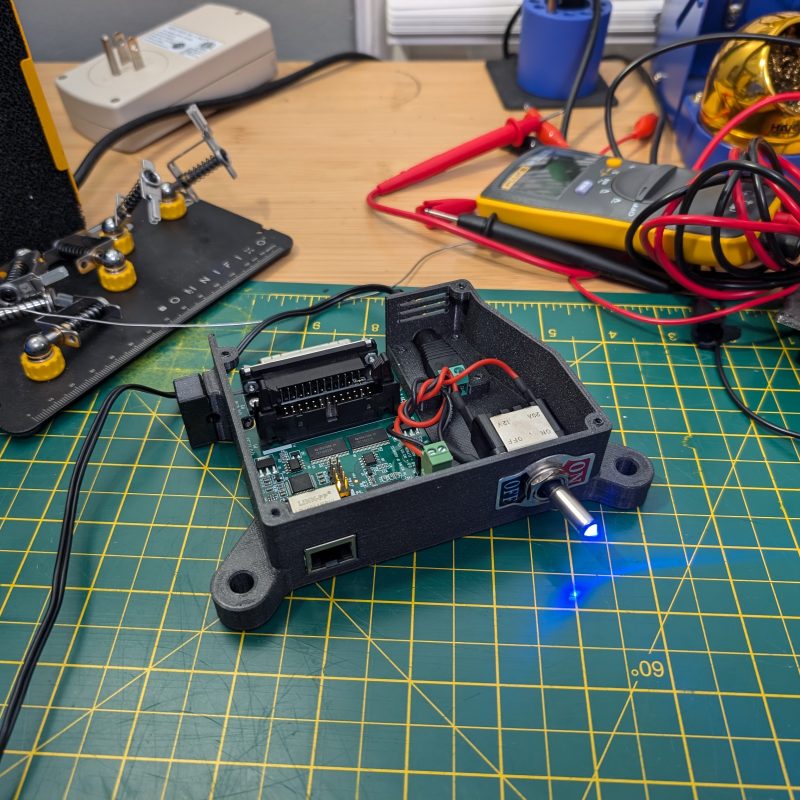

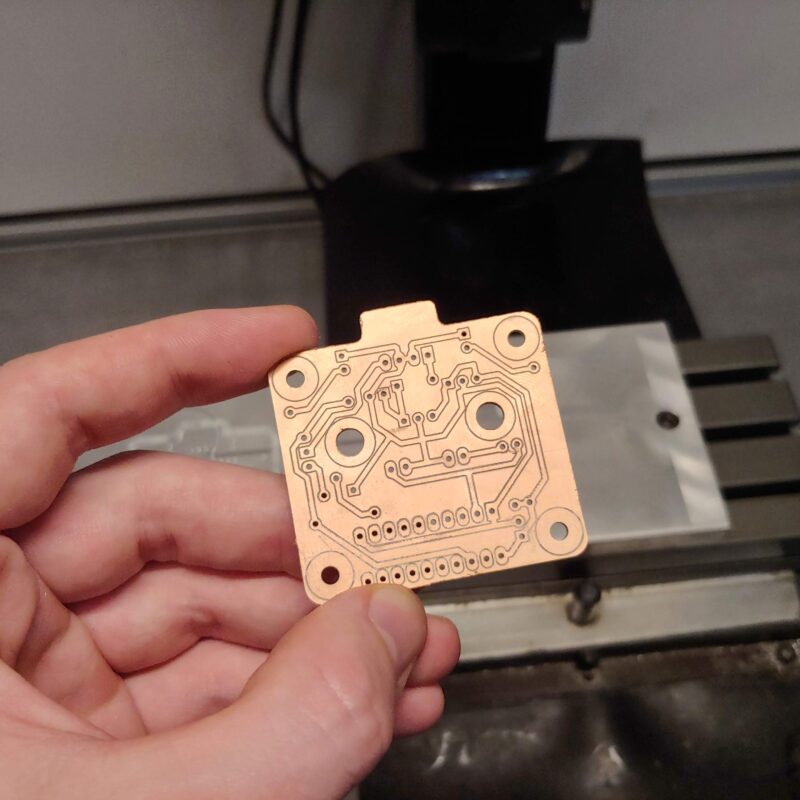

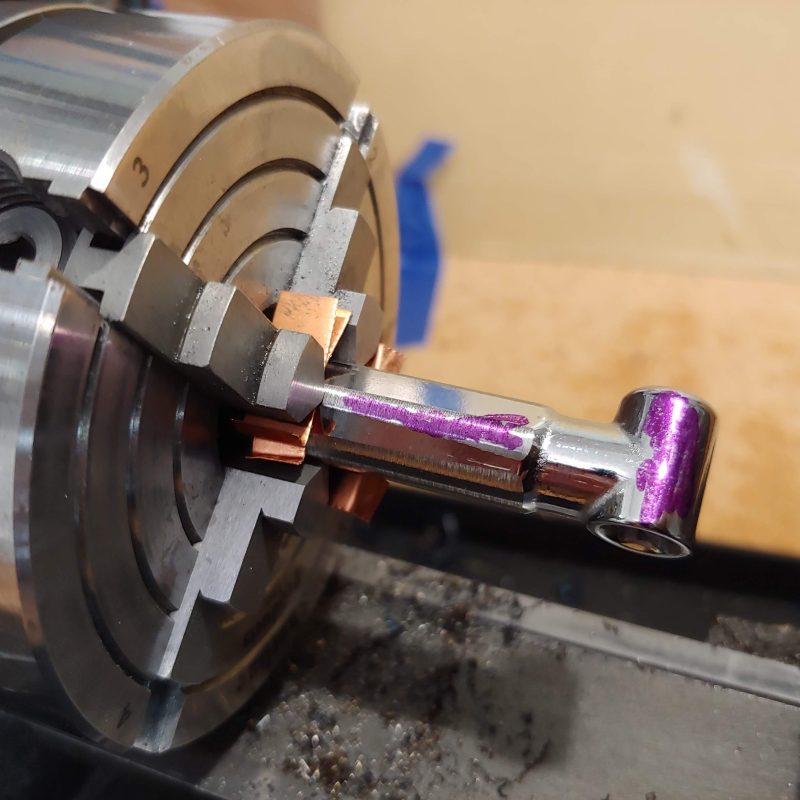

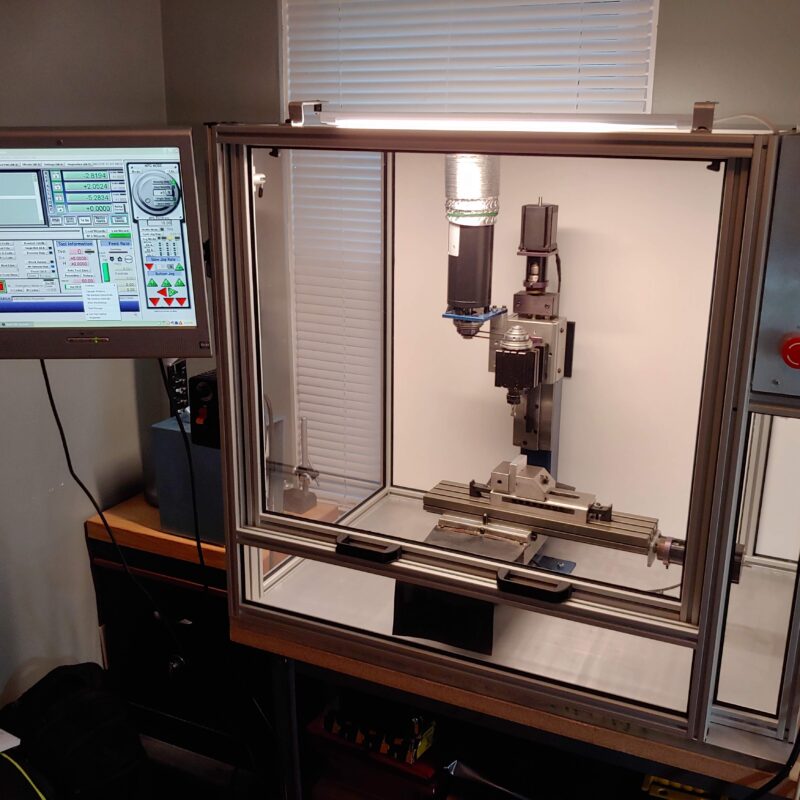

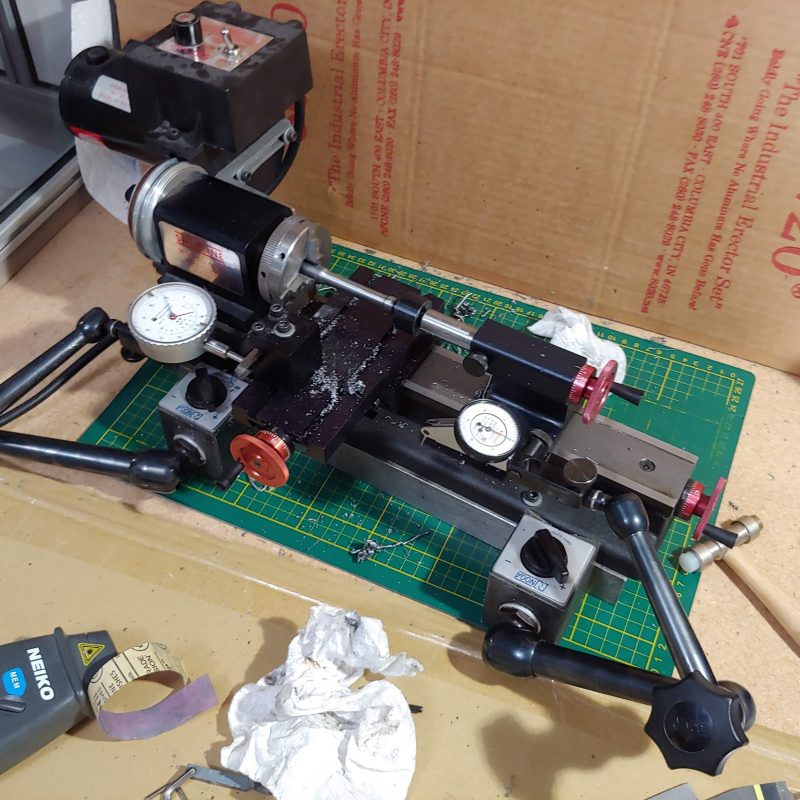

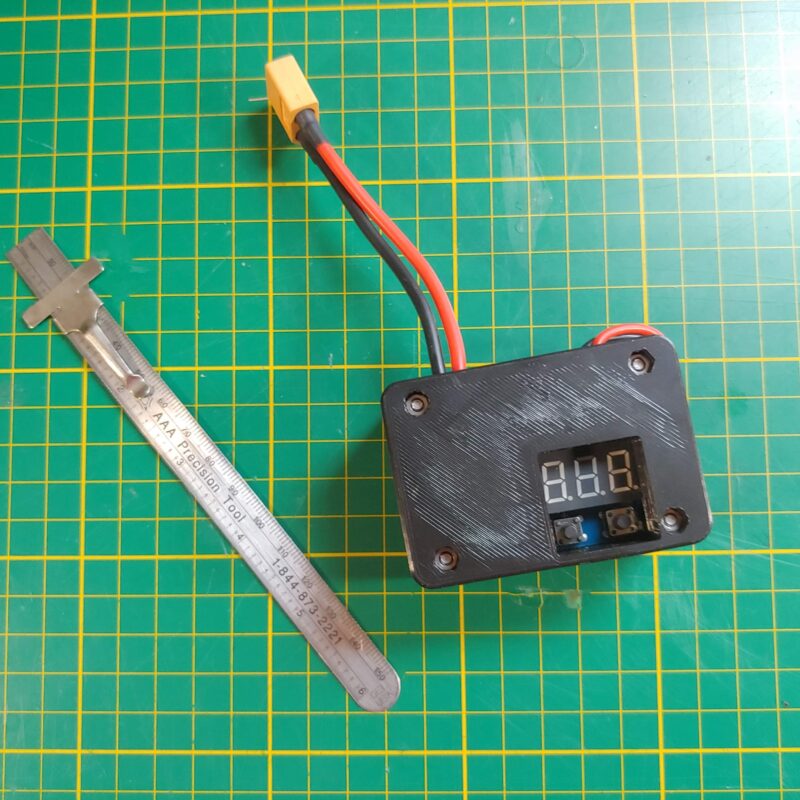

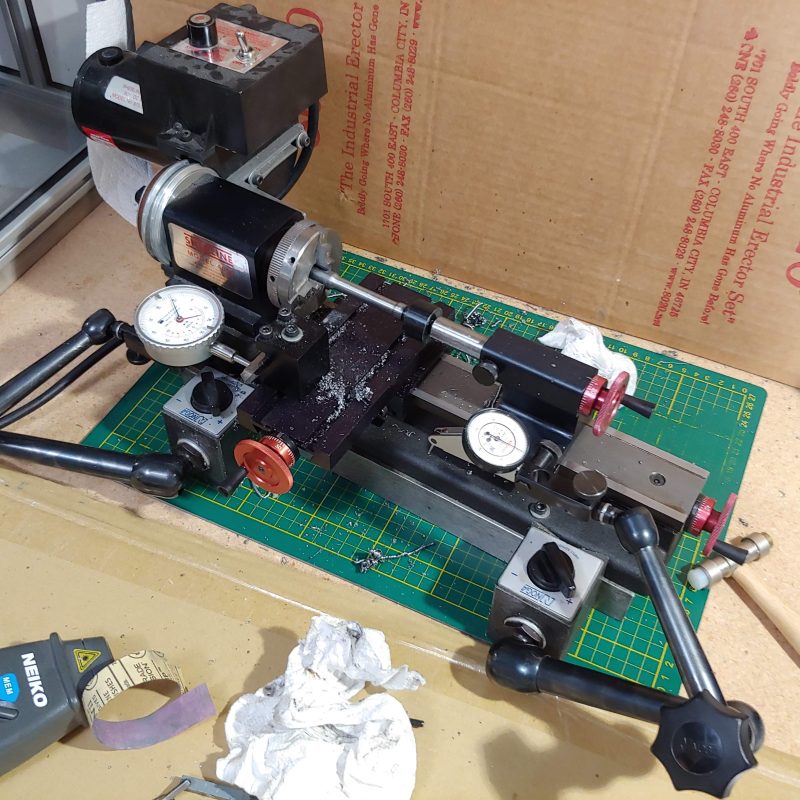

Personal Projects

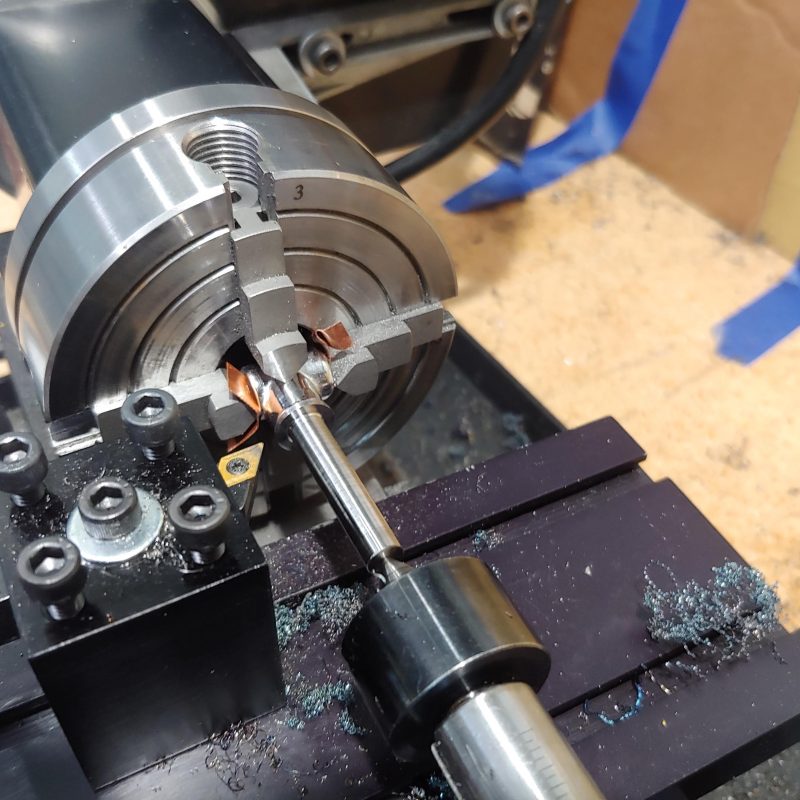

See the things I've built and the ridiculous problems I've tried to solve in my time off the clock!

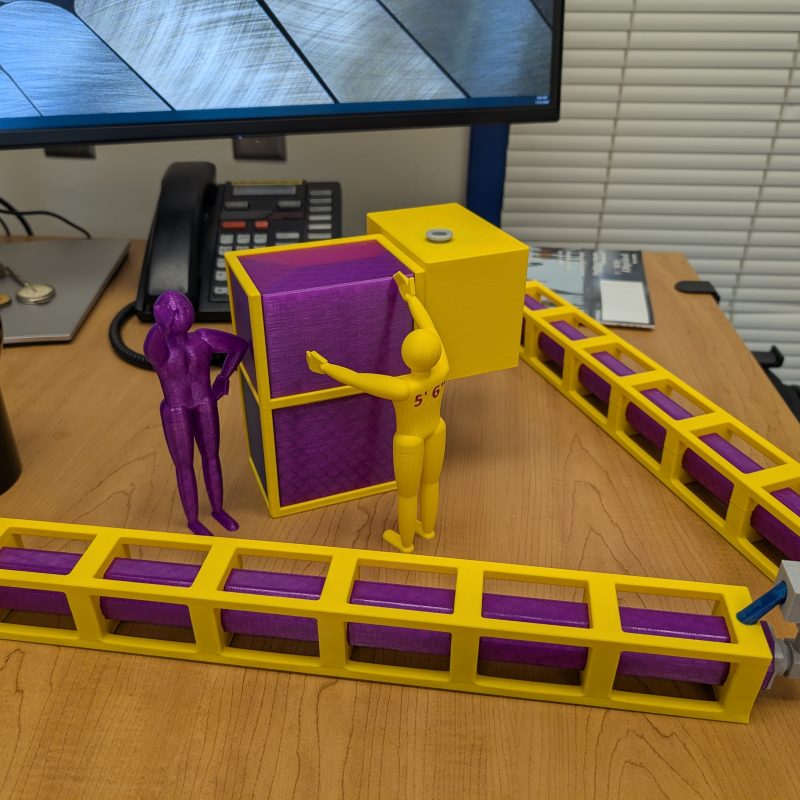

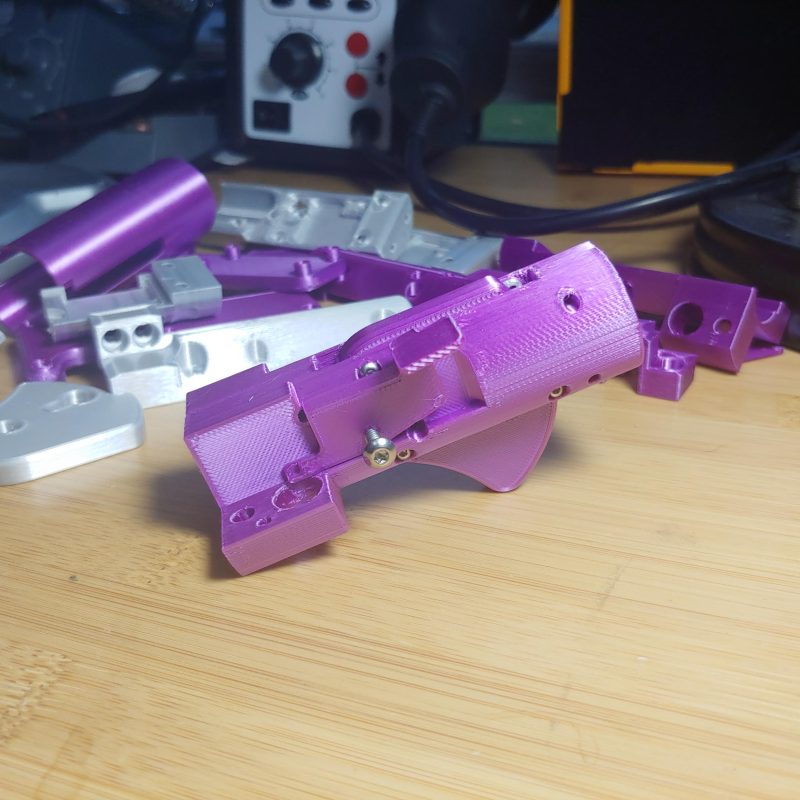

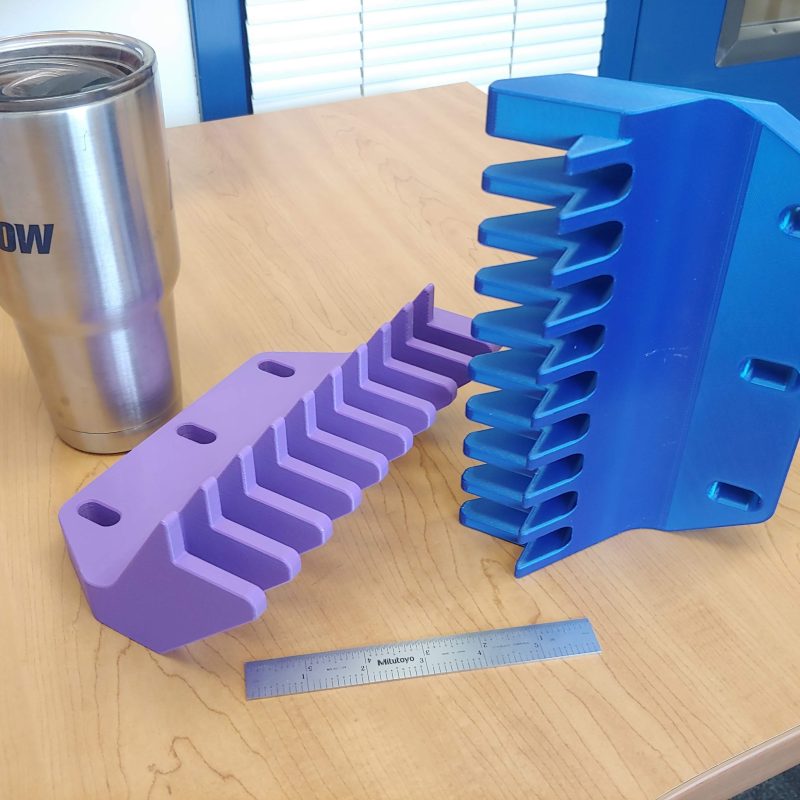

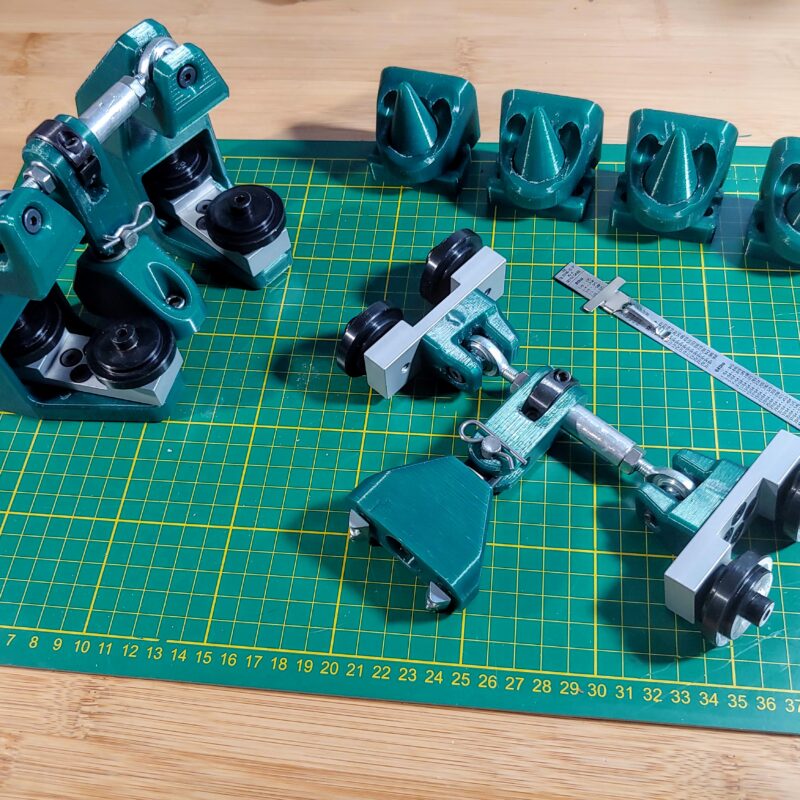

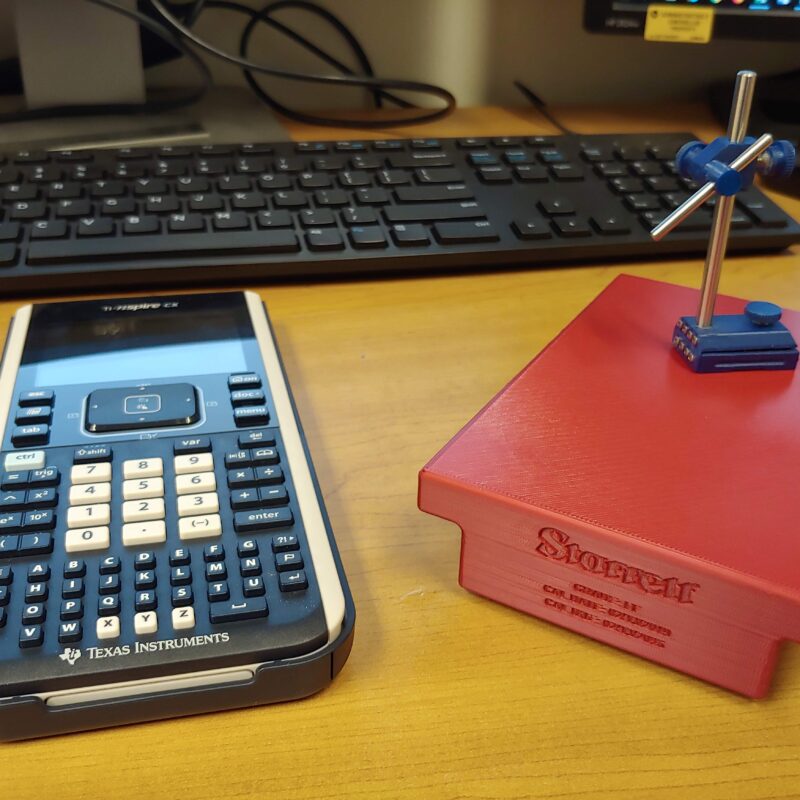

3D Prints and Misc.

A collection of small projects and things I've 3D printed throughout my engineering adventures.