After seeing a video about how the Knipex Cobra XS pliers could fit into a small Belroy wallet, I was completely enamored with the idea of carrying around a pocket toolkit built around the Knipex.

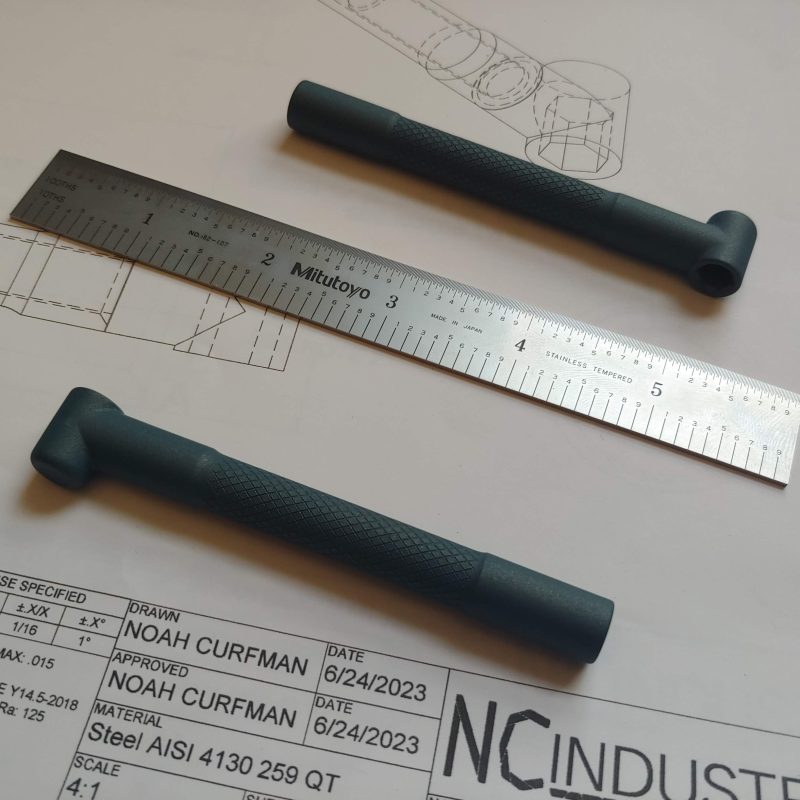

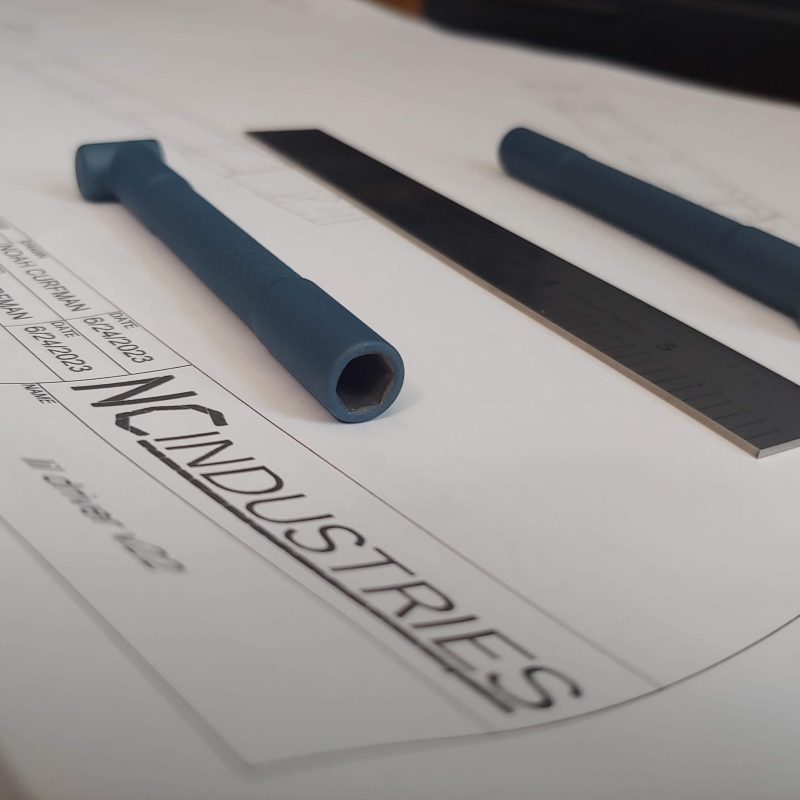

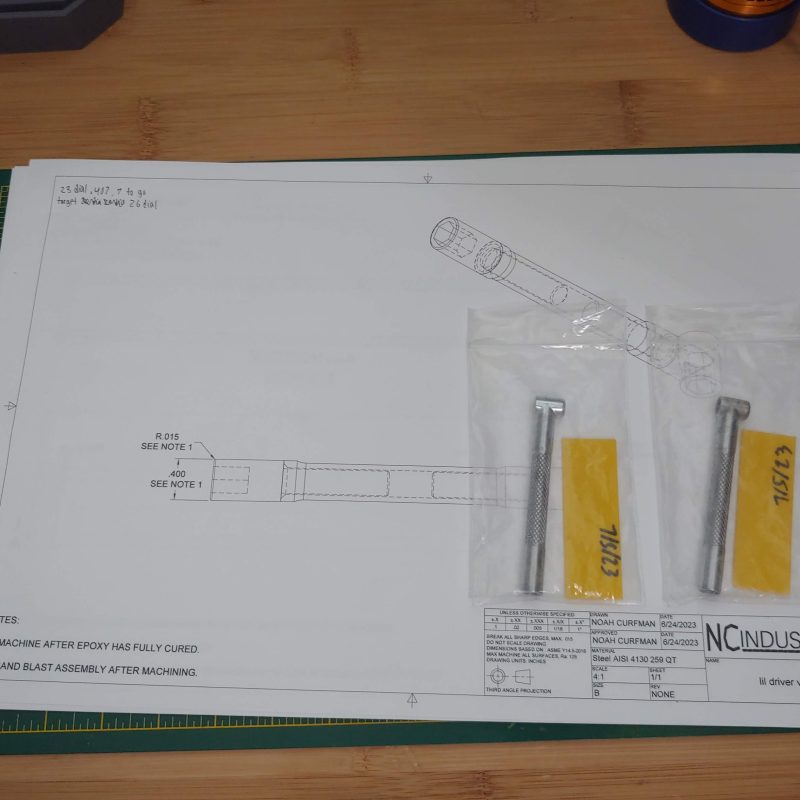

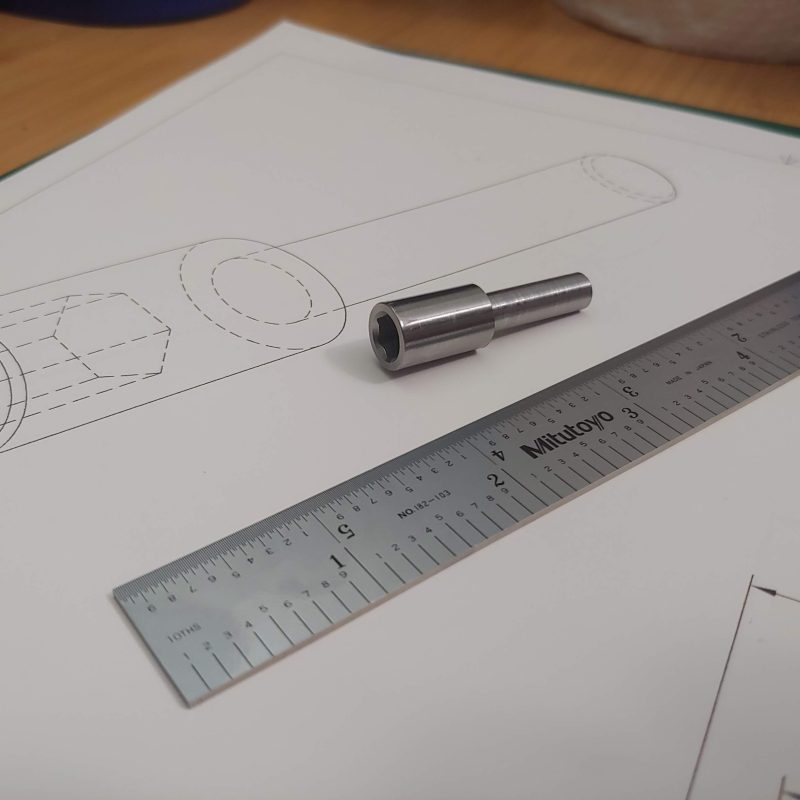

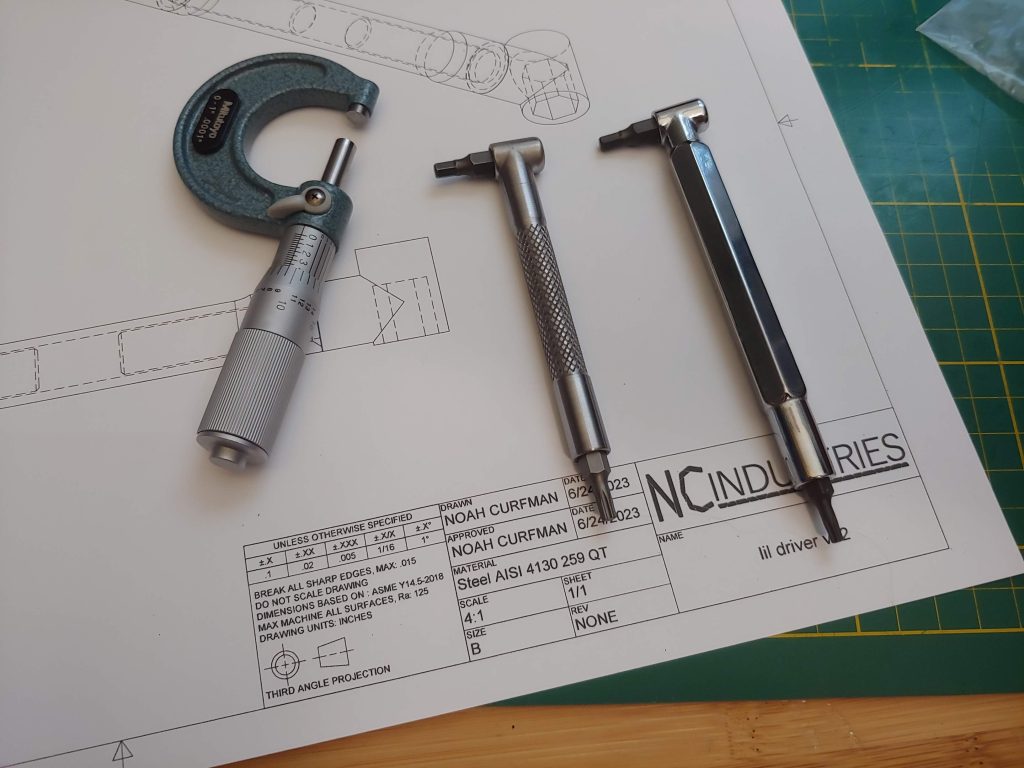

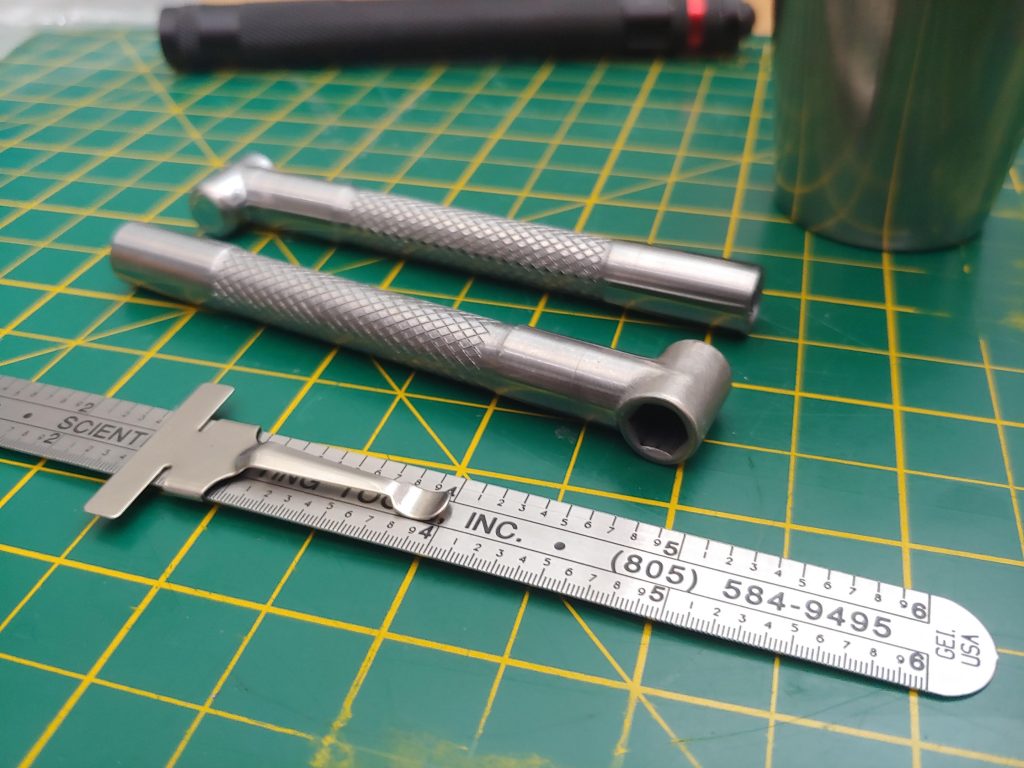

For small 1/4″ hex drivers in this class I much prefer a double-sided fixed driver to a one-sided ratchet. I bought the generic hex driver shown on the right in the below image and turned off the hex to make it a bit slimmer. After only a few days the height of it sticking out the wallet became annoying and I realized I needed another solution.

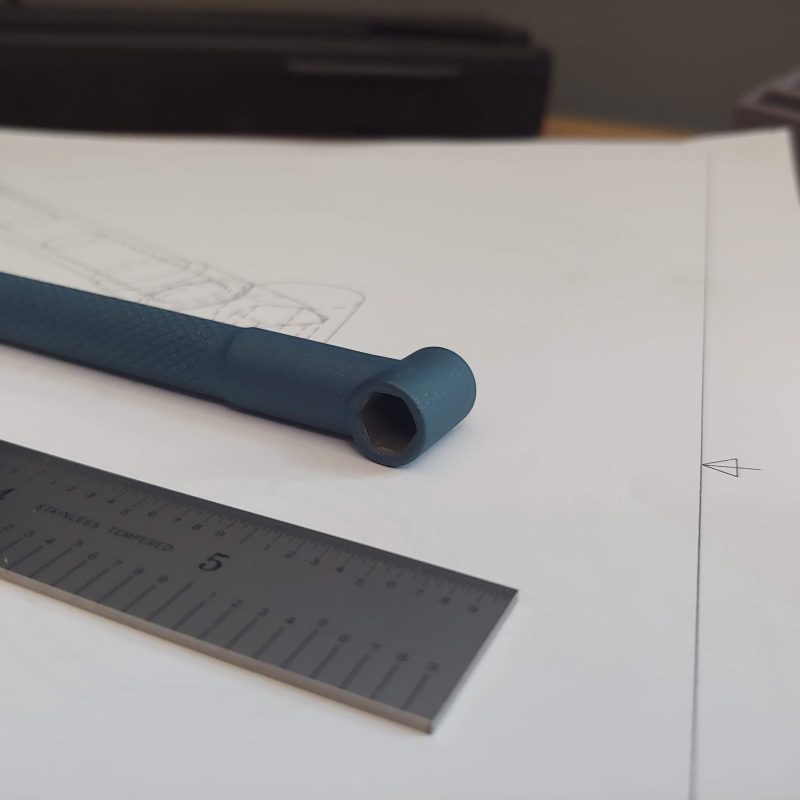

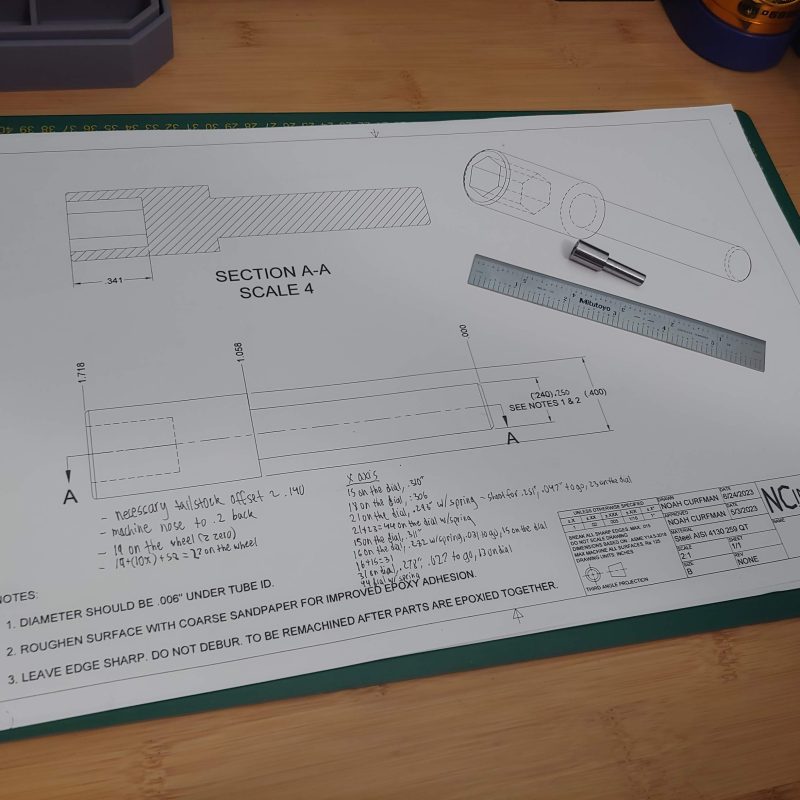

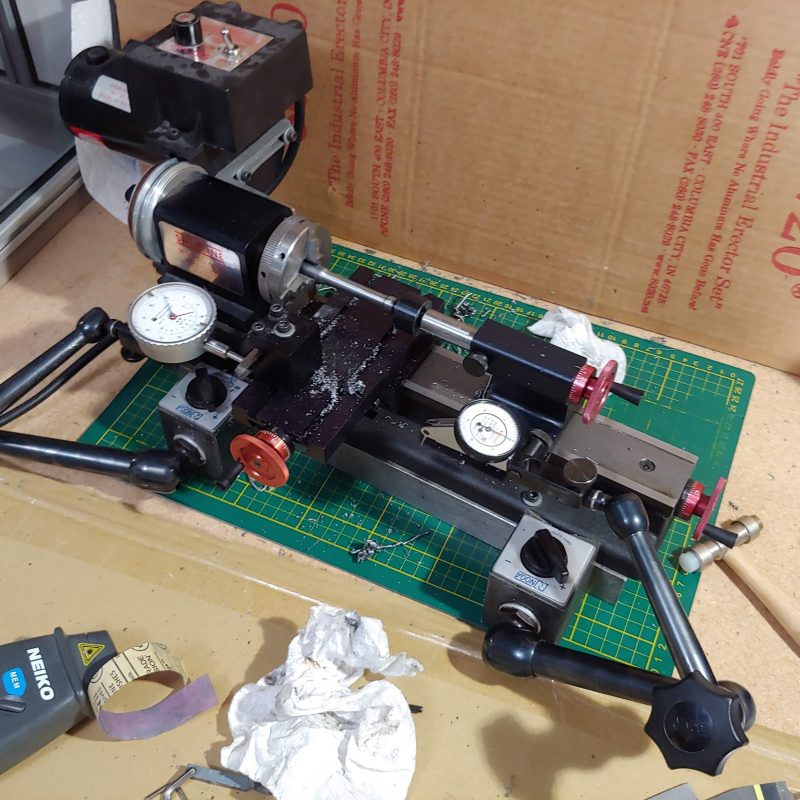

I realized there was no chance I was going to find a driver the right length, so I decided the best path forward would be to make something custom. The internal hexes on the ends of a 1/4″ driver represent a challenge for a hobby machinist. To make the driver as compact as possible, they need to be forged in, broached, or cut with an EDM sinker. None of those options were very feasible in the little machine shop I have in my second bedroom.

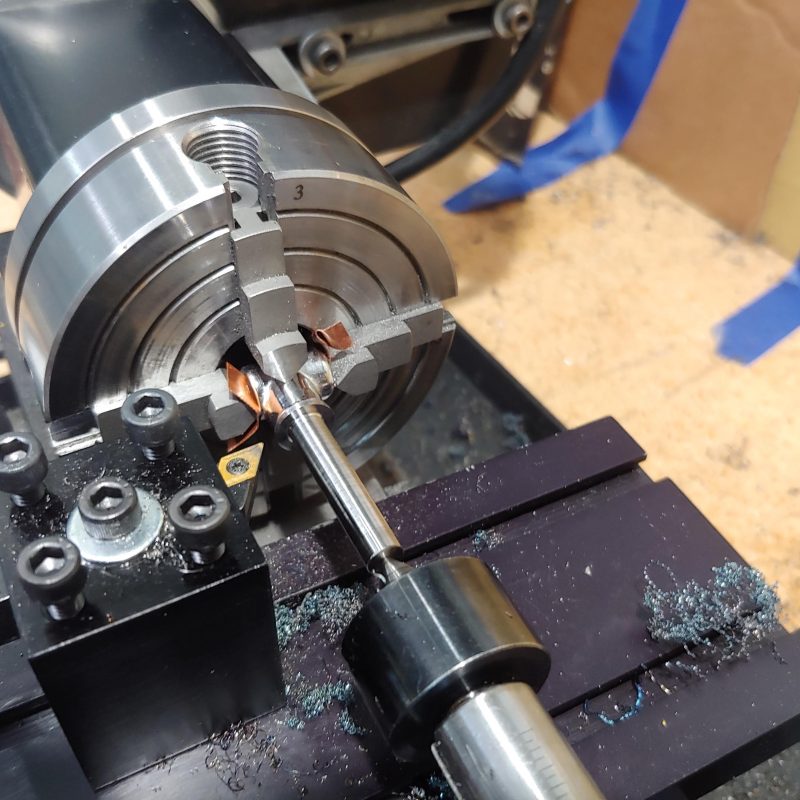

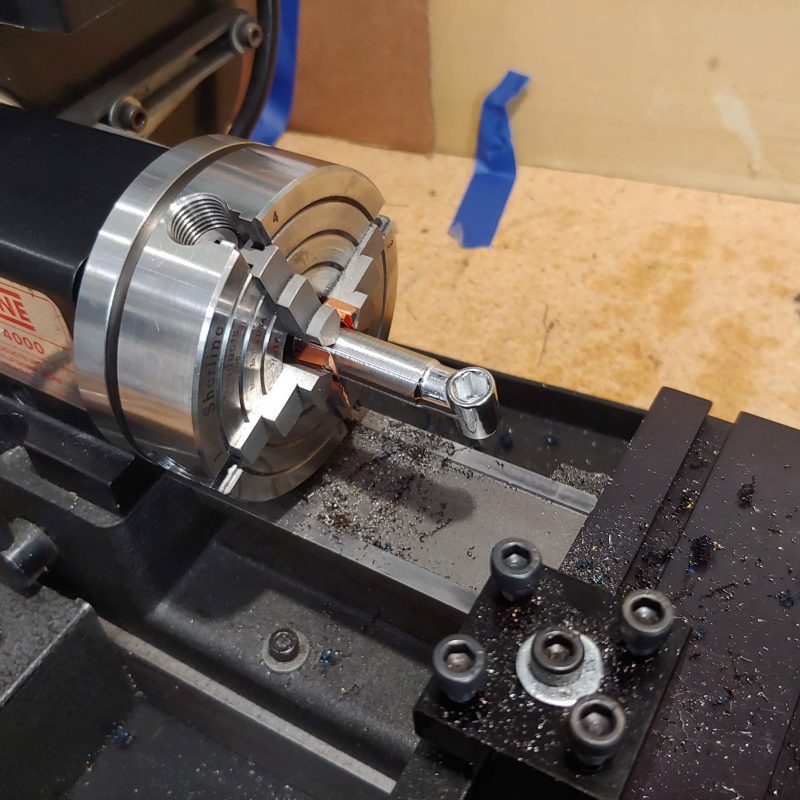

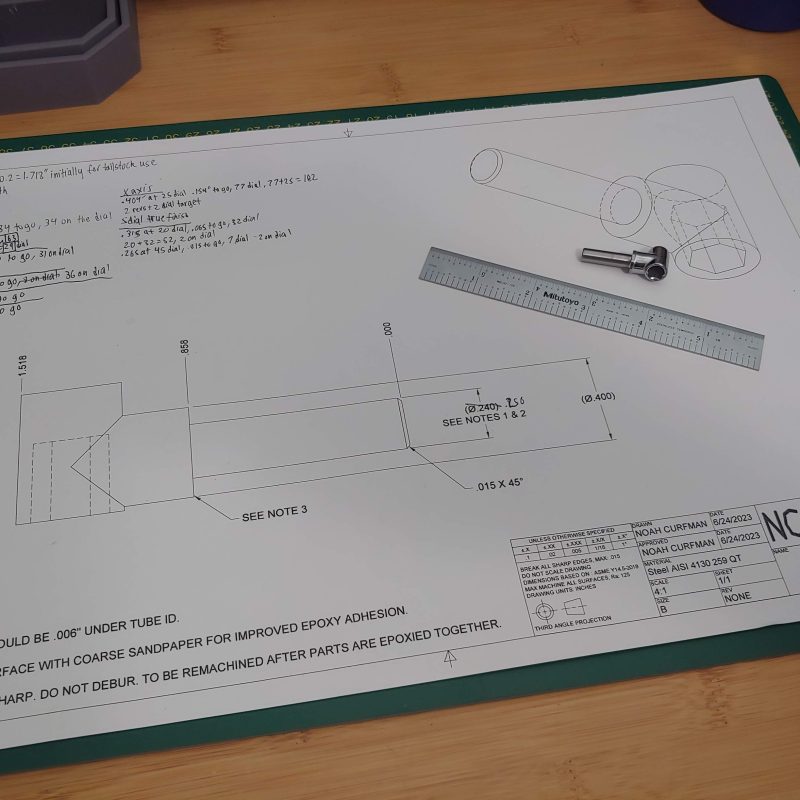

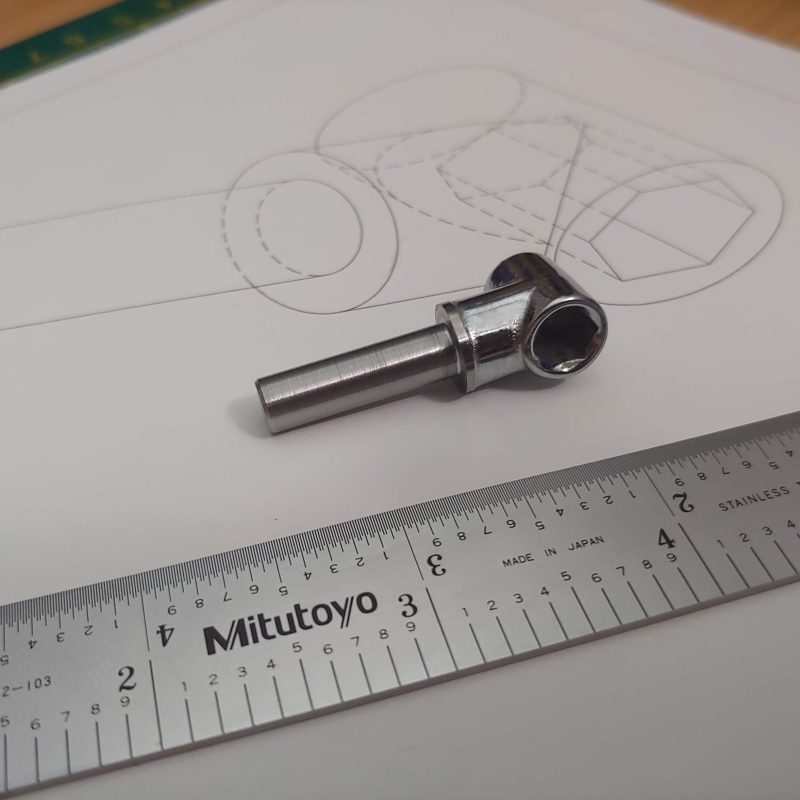

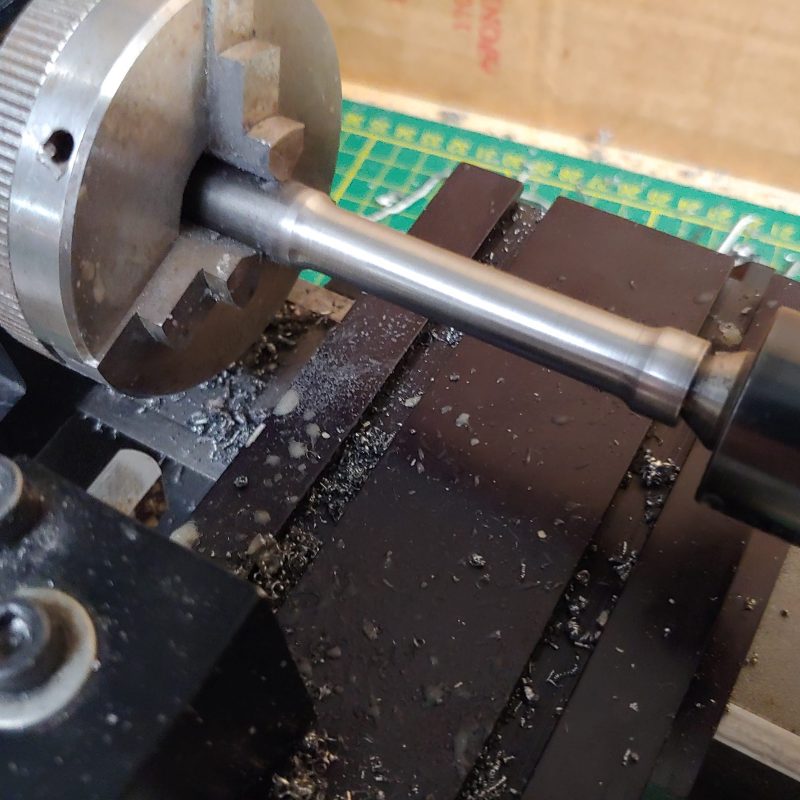

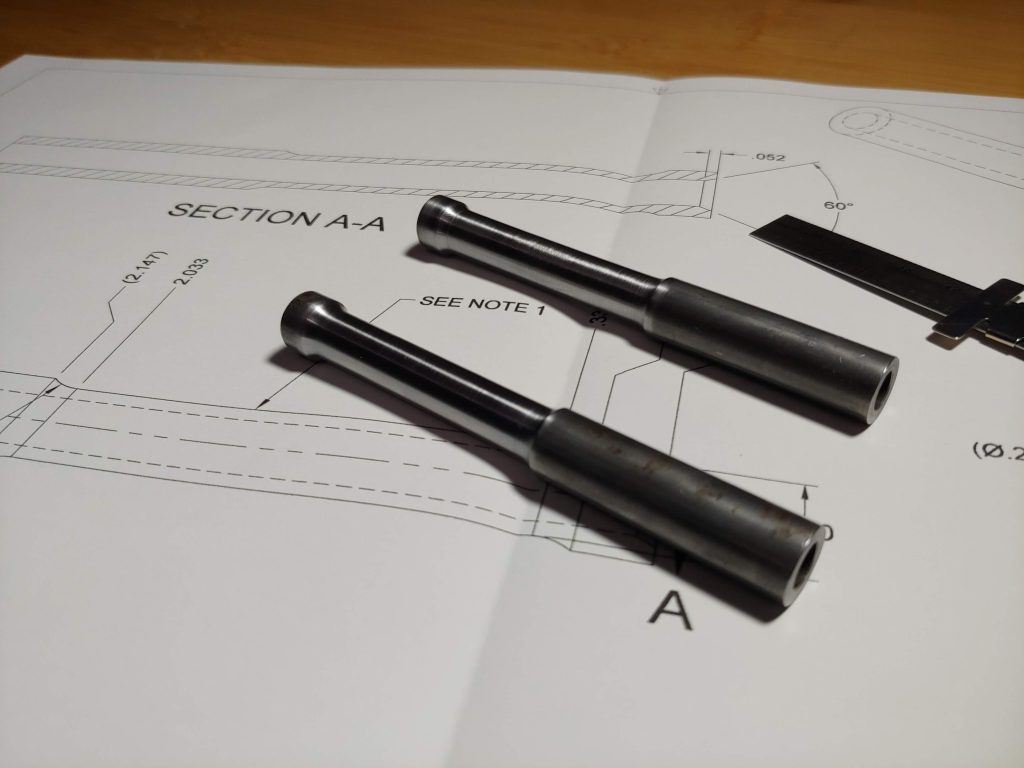

Instead, I opted to cut the ends off the driver I had and glue them into a 4340 barrel machined to the length of my choosing. These things were tough to cut! I burned through a pretty good number of carbide inserts relative to how much cutting I did.

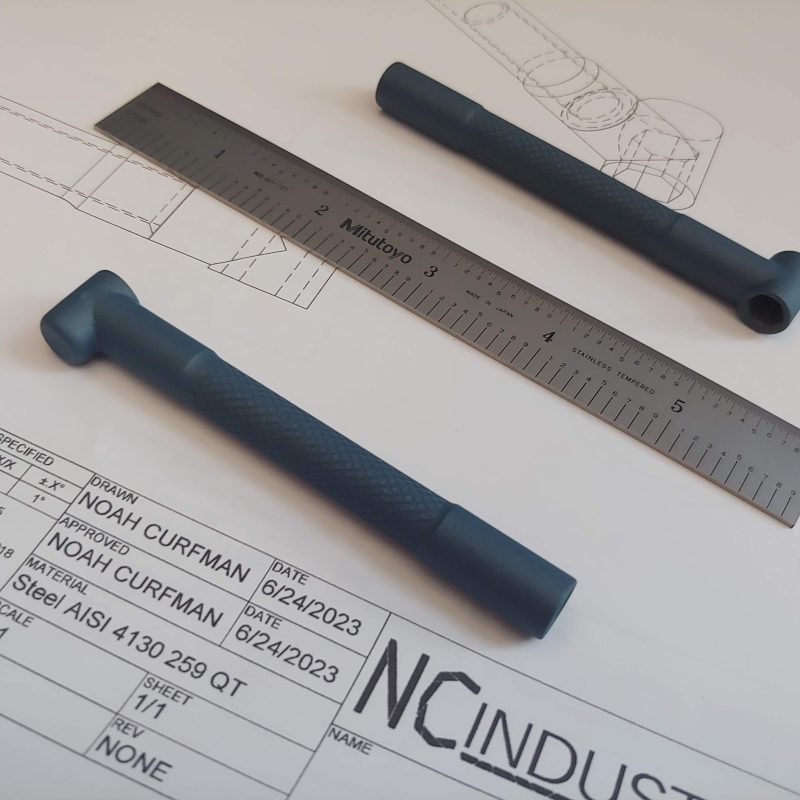

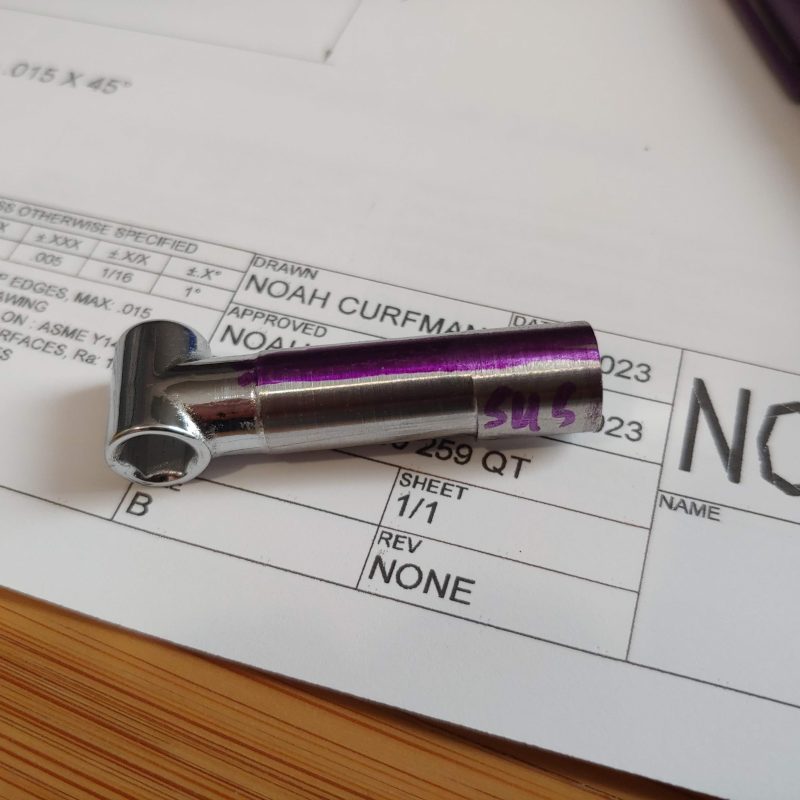

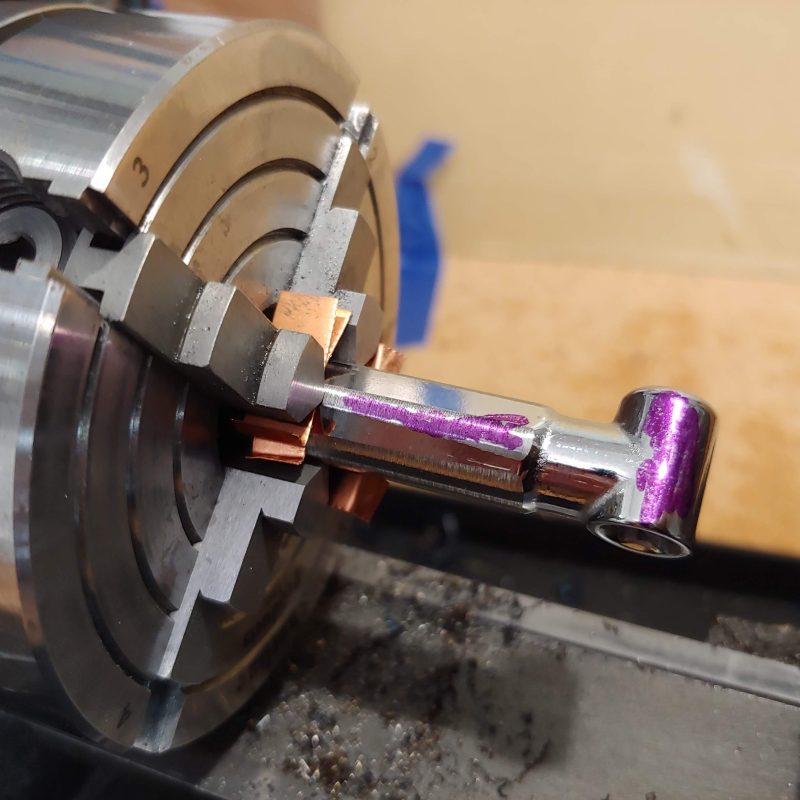

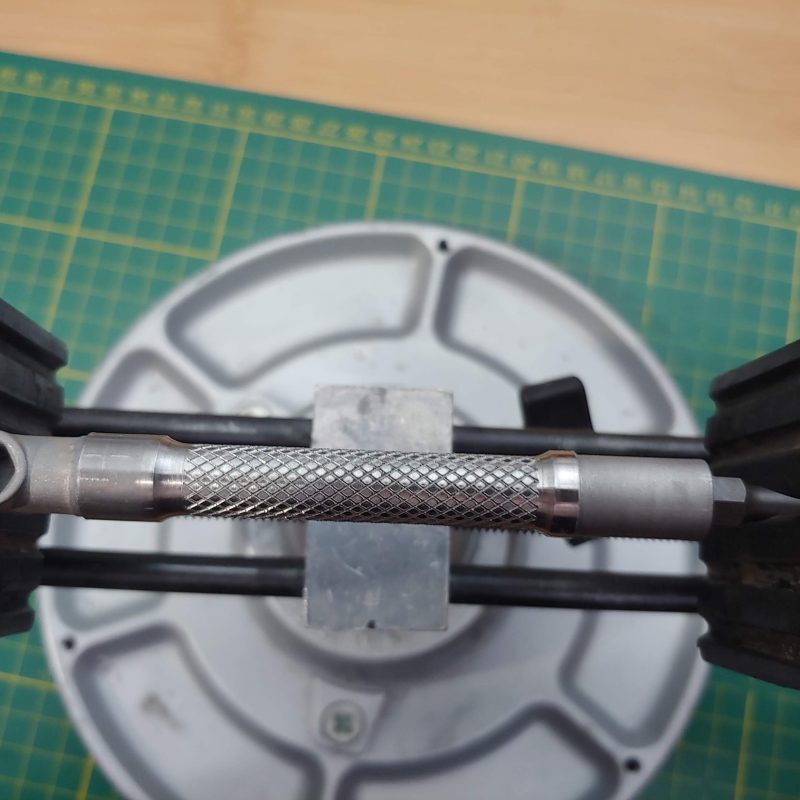

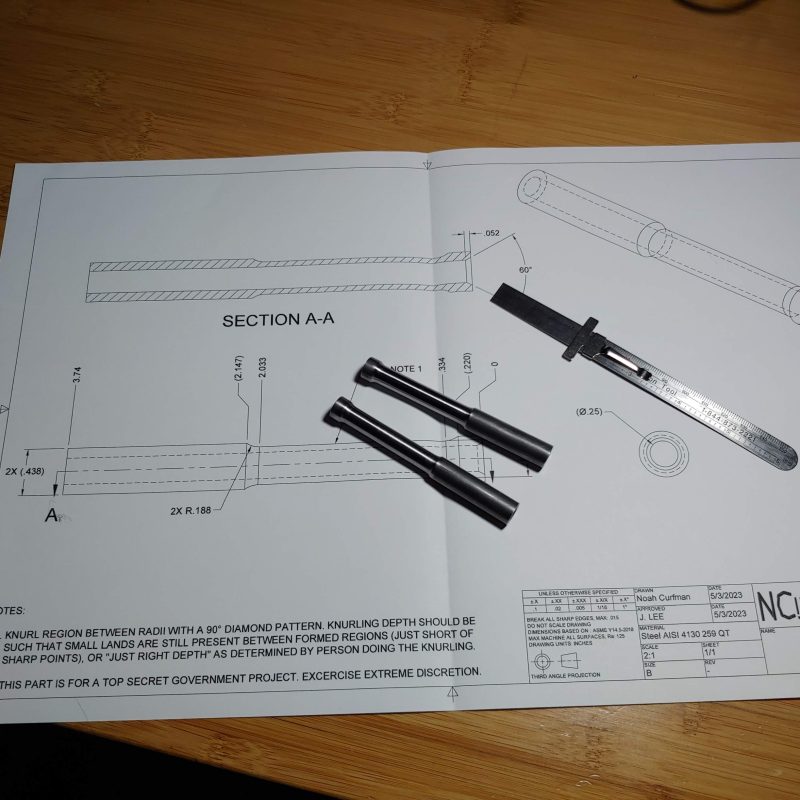

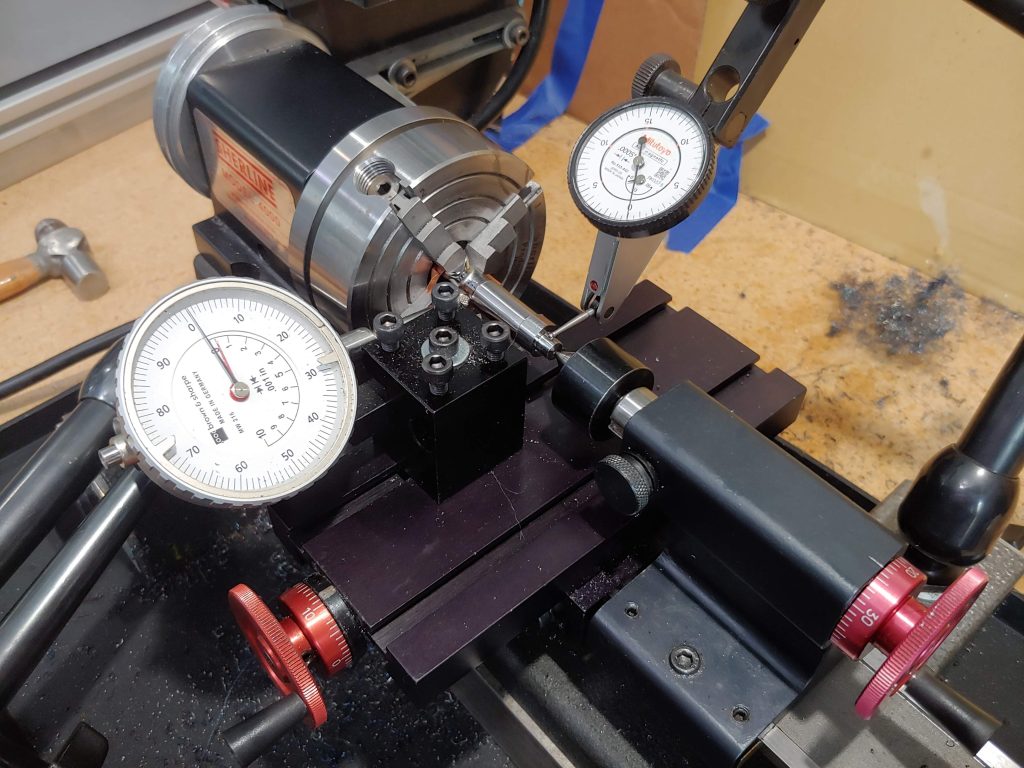

I made the barrel blanks with a relieved section in the middle so the knurling that was added later wouldn’t scrape against the leather of the wallet. Additionally, I ground a form tool to put a healthy radius on each side of the knurl so the step wouldn’t catch on the wallet when putting the driver away either. While I waited for a friend to add the knurling to the barrels, I bought another hex driver so I could make two for the sad day when I lose the first one. The internal hex ends on that second driver were unbelievably out-of-true to the body. That’s what I get for basing a project on $8 tools from Amazon!

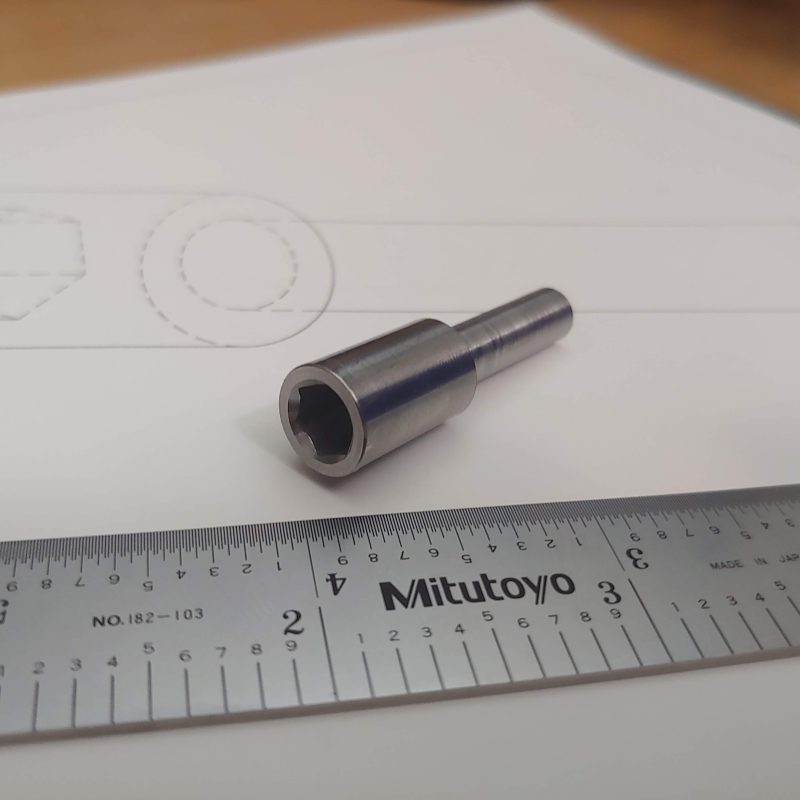

Once the parts were finished, I glued everything together with a little bit of JB Weld. I left a .006″ gap for the JB weld to fill and put a healthy chamfer on the ends of the barrels to give the JB Weld somewhere to go as it pushed out. After I trued up the OD on the lathe you could barely tell the drivers were 3 parts.

I sandblasted the drivers and sent them out for a low-temp blue Cerakote. I would have much preferred powder coating or a high-temp Cerakote coating, but I was afraid that getting the magnets too hot might demagnetize those cheap magnets and make all my hard work futile.

At Last, I finally had a driver that fit perfectly in my wallet. I 3D printed a little TPU holder for 8 shorty, 20mm long hex bits that are used in the Linus Tech Tips screwdriver. I leave a standard length 4mm hex in the wrench at all times to give me a little extra leverage on the short end. I’ve been carrying this around for a few years now, and I still smile every time I use it!