Particle accelerator beamline installation vehicles are typically designed to install enormous, durable magnets weighing up to twenty tons. Electrostatic septa are light-weight, and usually contain ceramic components that can be easily broken if significant accelerations are applied to the vacuum vessel. For these reasons, custom carts using pneumatic air bags are almost always developed for transporting and installing septa. For the Mu2e septa a grad student had already engineered and fabricated a steel transport cart. It was my task to add a pneumatic airbag system for leveling and lifting a septum to install it into the beamline.

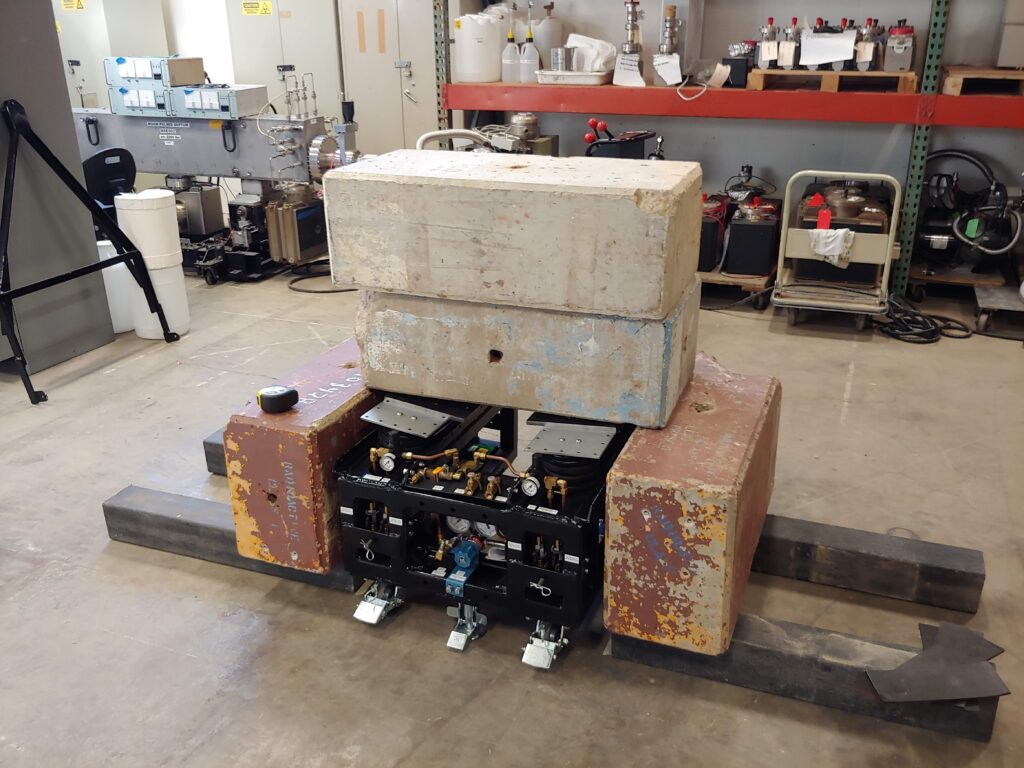

The previous designer of the cart left plenty of room for a very simple pneumatic system that used an external air connection. Unfortunately, after the cart had been fabricated the system requirements changed considerably, requiring an onboard air supply and independent control and venting of each of the four airbags. By using a bottle mount intended for off-road vehicles I was able to squeeze a small nitrogen bottle within the frame of the cart. Creating a 3D model of the entire pneumatic system ensured that all the components would fit prior to purchasing, and made routing all the piping a much easier task. After installing and load testing the system, the cart was able to successfully lift and transport the septum with ease and provides excellent control over the orientation of the device.