The 100-meter-long Matter-wave Atomic Gradiometer Interferometric Sensor, or MAGIS-100 for short, is an upcoming quantum project at Fermilab that aims to detect gravitational waves using lasers, free-falling strontium particles, and quantum superposition. As part of the engineering team for the project I design support, alignment, structural, and installation systems. The device at its core is a precisely aligned 100m long vertical vacuum tube attached to the wall of the Fermilab MINOS shaft. The entirety of the vacuum tube is magnetically shielded, and all materials used around the beam pipe must have low magnetic permeability.

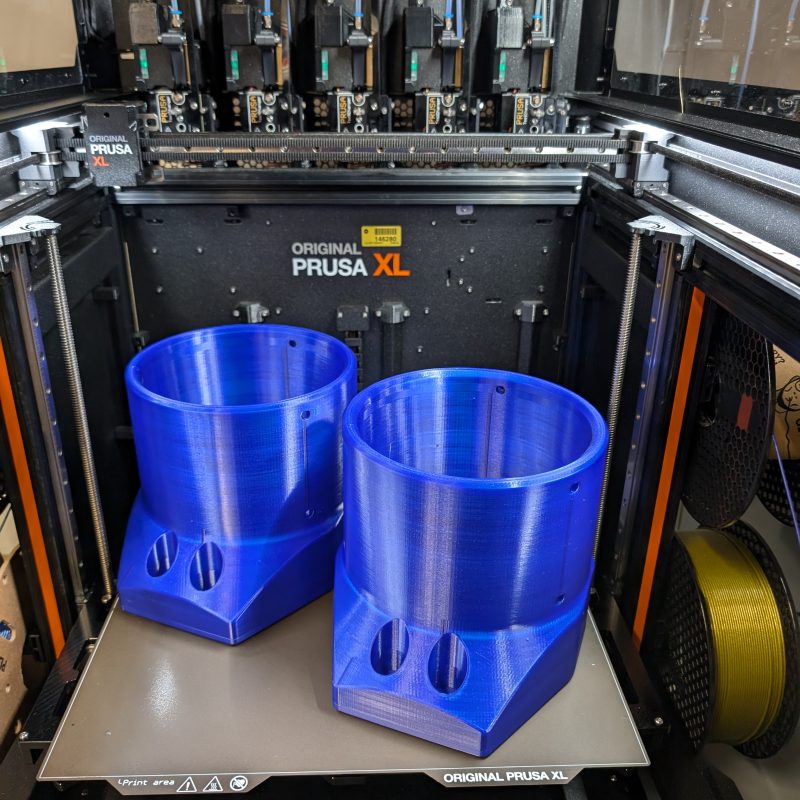

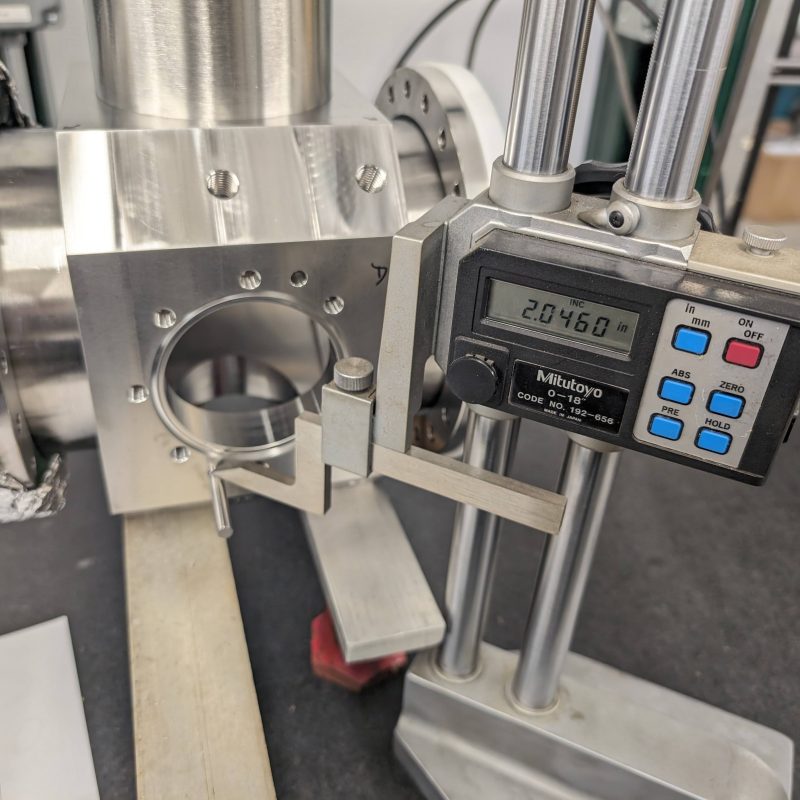

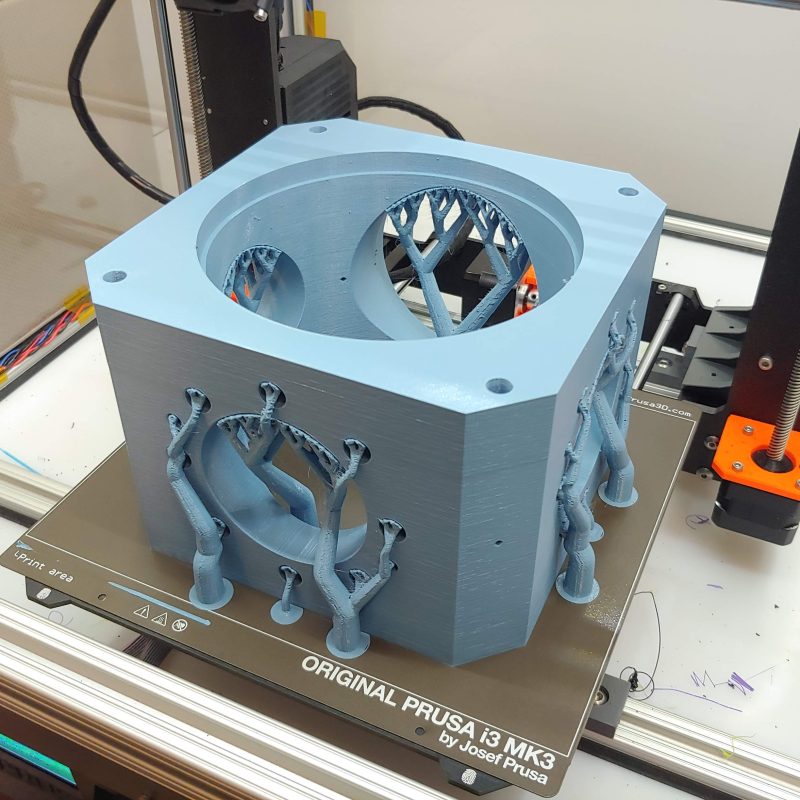

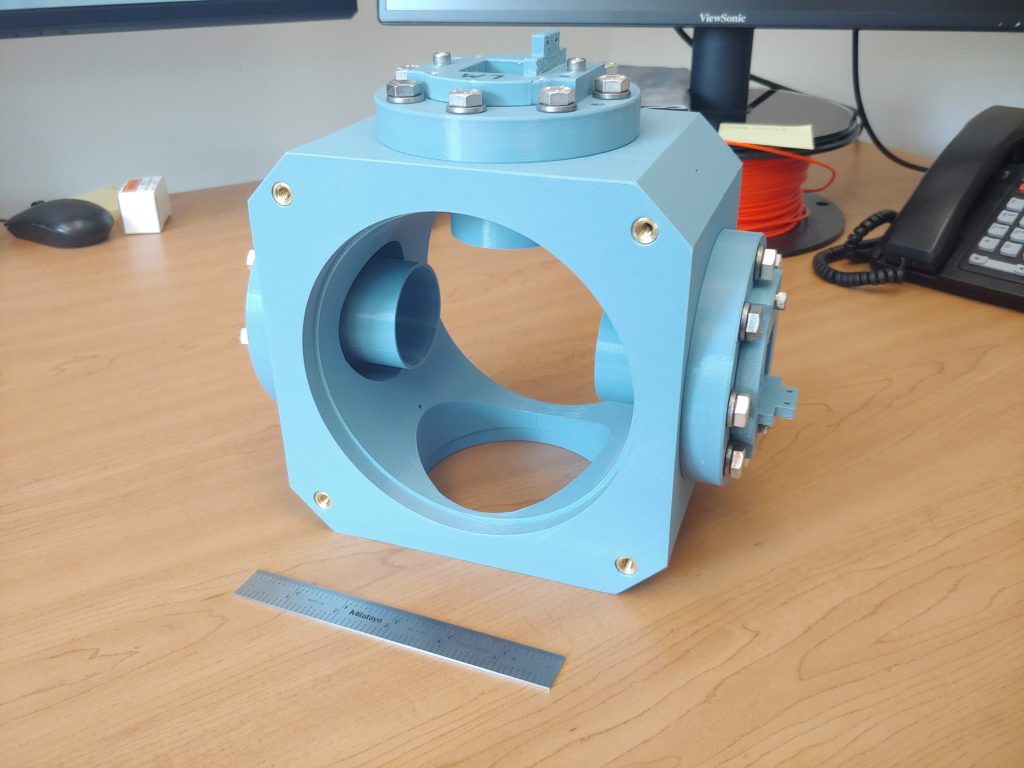

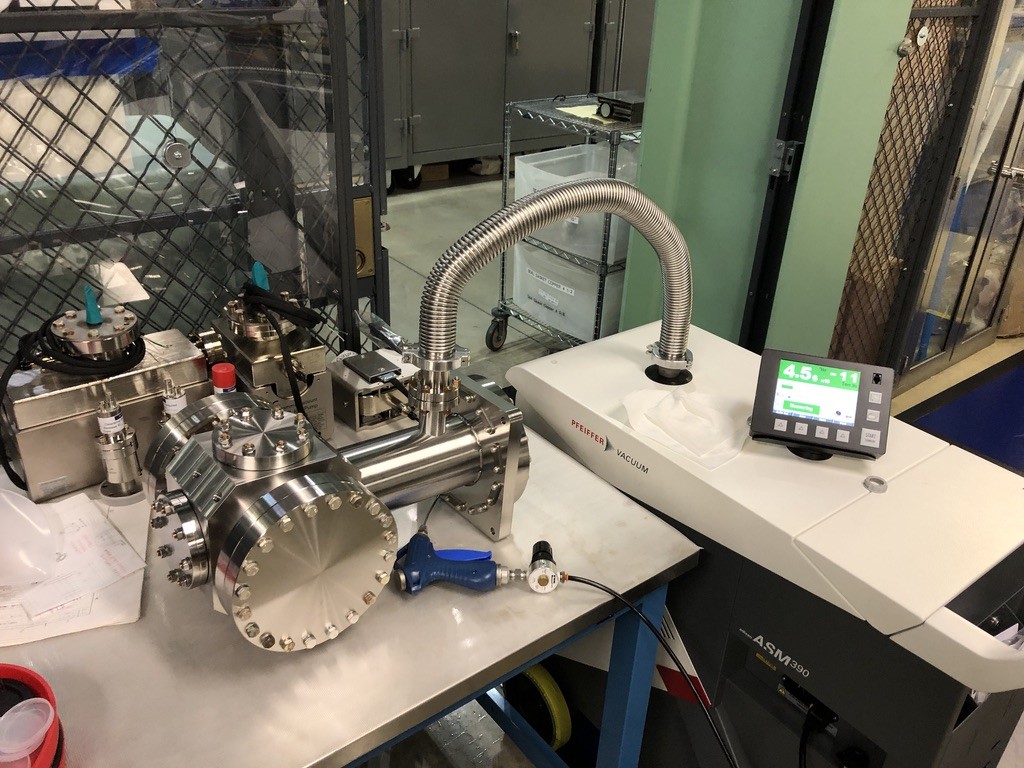

I’m responsible for the design of support structures, magnetic systems, various prototypes. Shown below is a vacuum chamber I designed for the experiment to meet some challenging physics requirements along with its 3D printed prototype.

This vacuum chamber is one of 17 that rest within the magnetically shielded, ultra-high-vacuum region of the experiment. To minimize magnetic disturbances, the chamber is made primarily from 316LN and is heat treated after machining and welding to remove magnetic grain structures within the steel. I designed the chamber to support and precisely locate 3 imaging cameras that track atom clouds as they fall, as well as a hefty 120 pound ion pump from the square flange on the right. After all the work that went into procuring the first chamber, I was pretty excited to unpack and get it on the test bench!

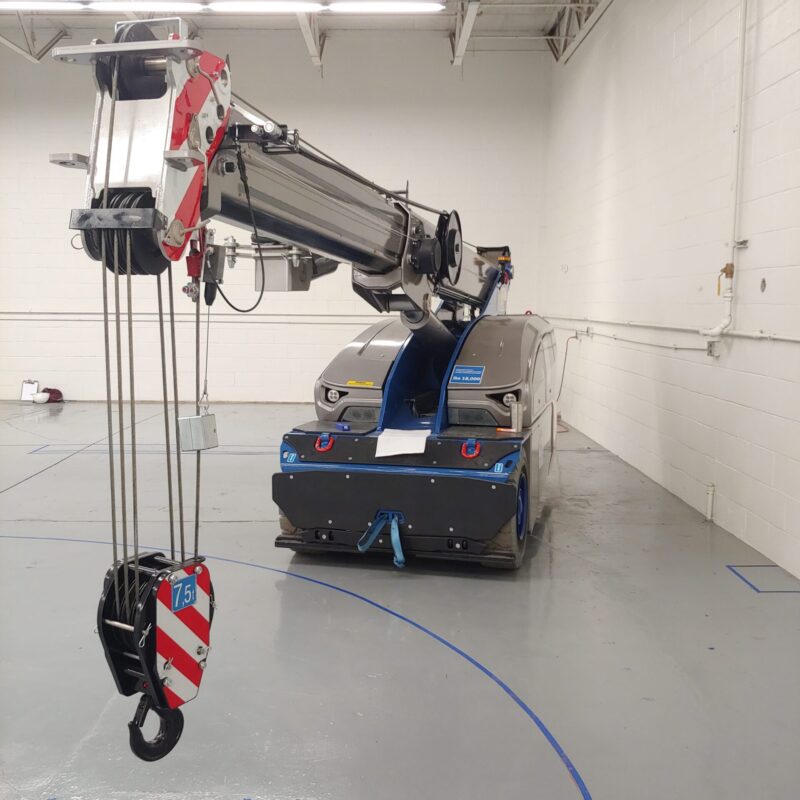

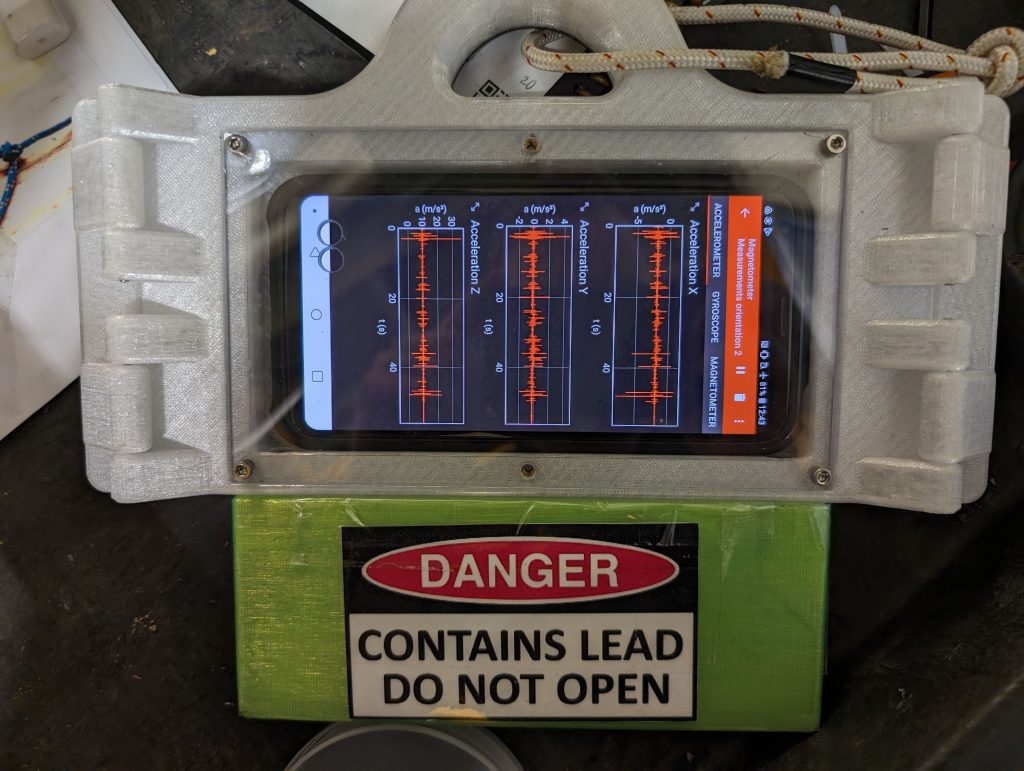

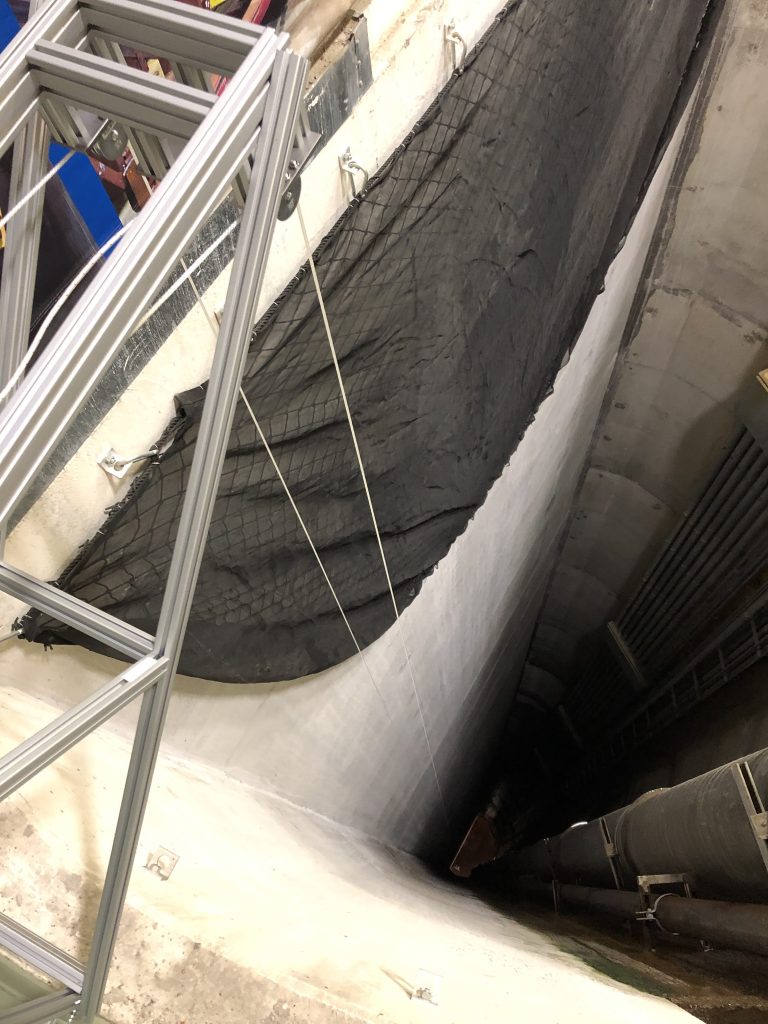

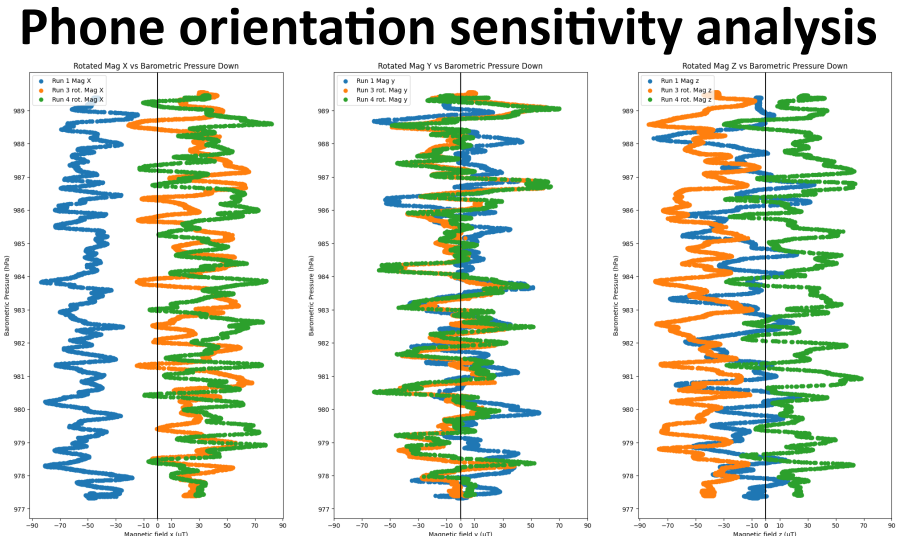

During the project the physicists grew concerned that the access shaft we were installing the experiment in, which was never intended for this purpose, may have troublesome magnetic fields that would cause issues with the data. As a first pass at the problem, I developed a low cost fixture that allowed me to lower my phone down the shaft along two tensioned ropes to maintain its orientation. A free app called phyphox gave me access to the phone’s built in magnetometer and barometer. By equating the barometer readings to elevation, I was able to get a rough approximation of magnetic fields within the shaft as a function of height.

By repeatedly lowering the phone down at different orientations, I was able to cancel out errors caused by magnetic components within the phone case and errors of the phone’s magnetometer. To our surprise, the data we got from this endeavor ended up being enough to satisfy the physicists. We were able to avoid the complex task of building a more precise measurement system we could lower down the shaft based on this data. My Github repo with the data and my report on the topic can be seen here for the especially curious: https://github.com/ncurfman/MINOS-Shaft-Magnetometry

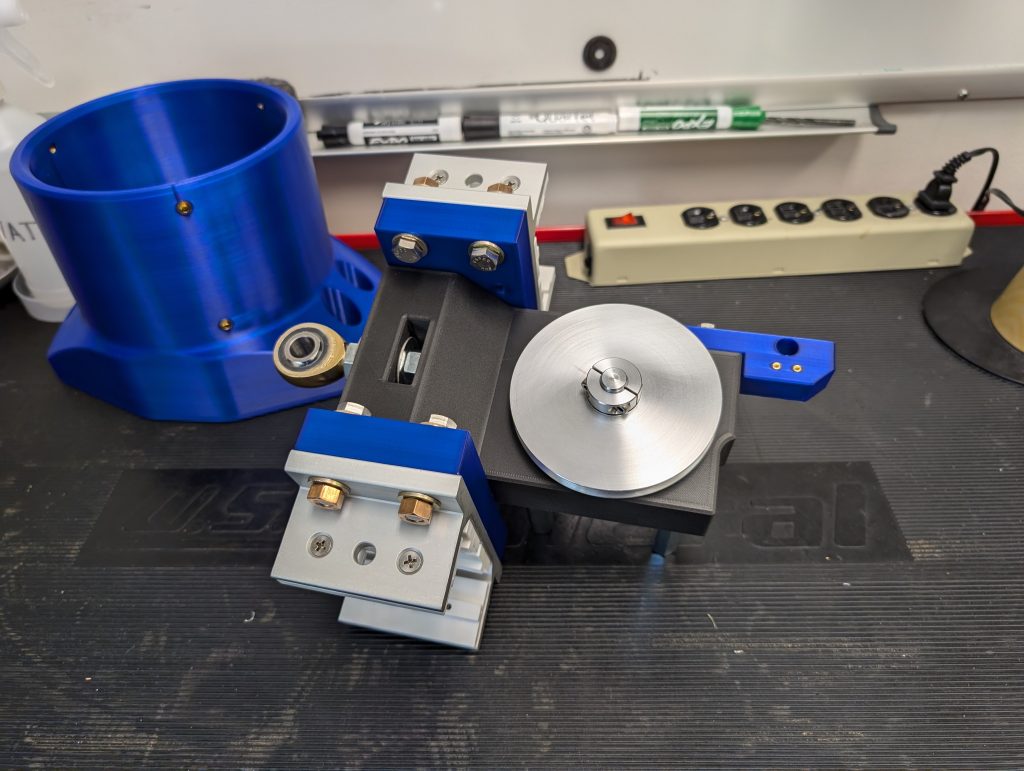

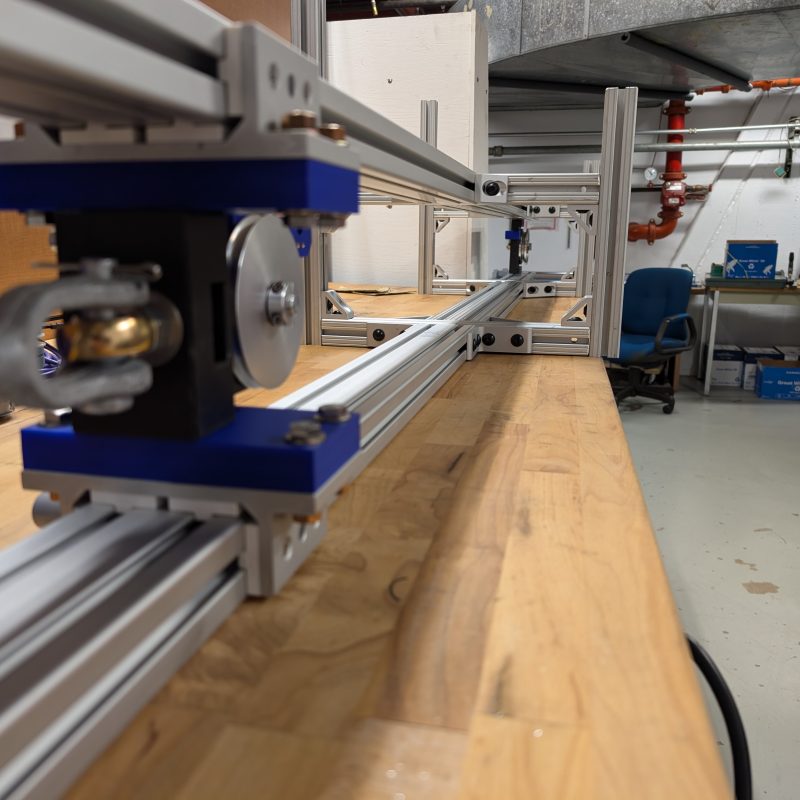

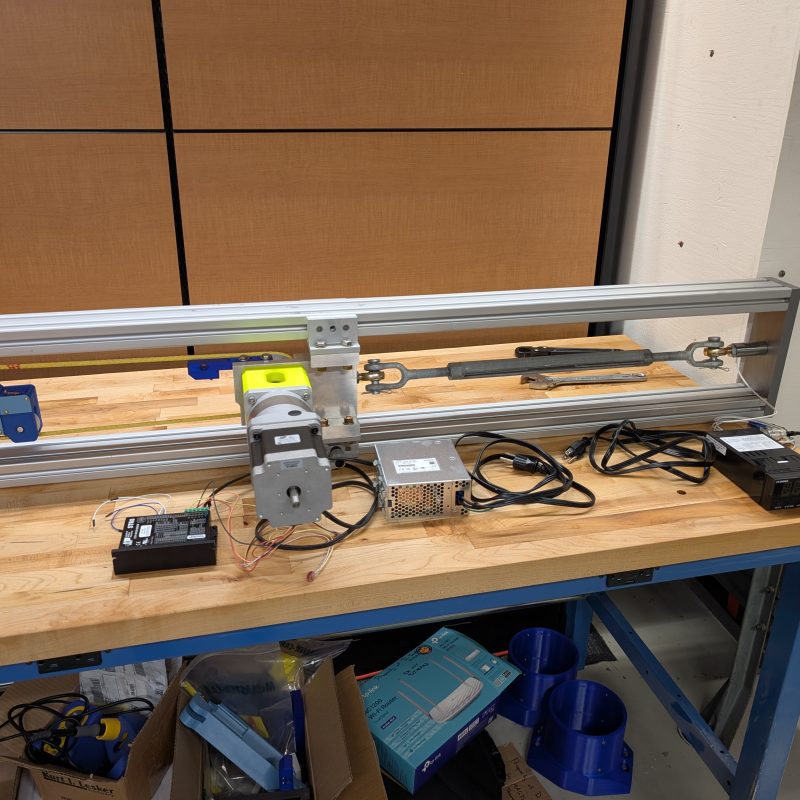

Building a 100 meter long experiment entirely from non-magnetic materials is quite costly. As a result, some small components need to be made from at least partially magnetic material. Simulating the effects of small magnetic components is costly and error prone, so I helped design a system that allows the project to check sections of beamline for magnetic anomalies before, during, and after assembly.

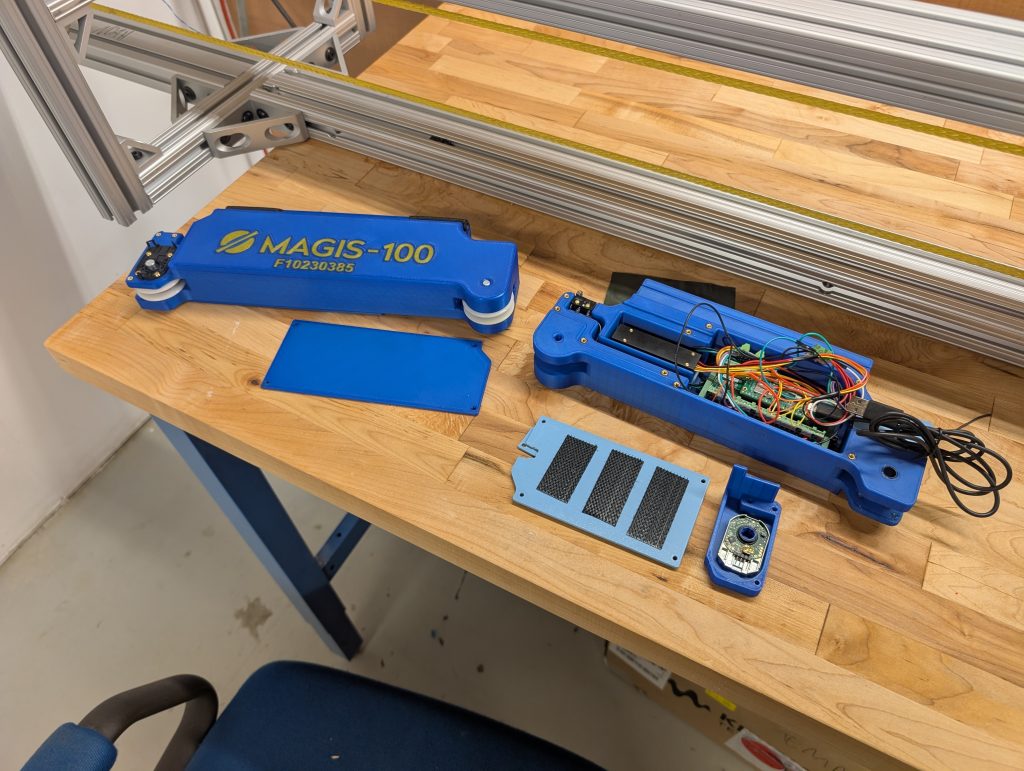

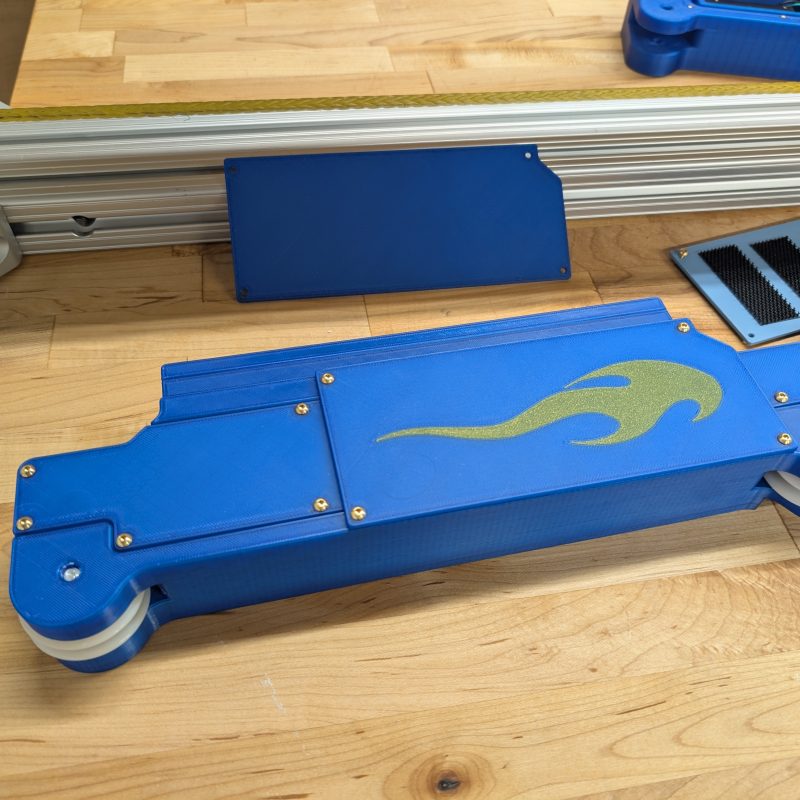

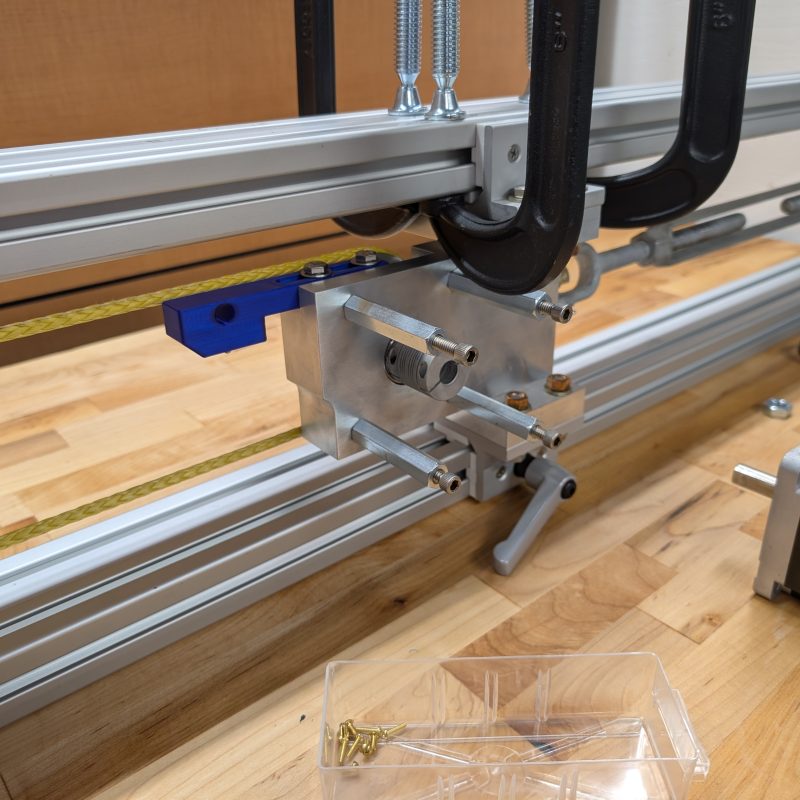

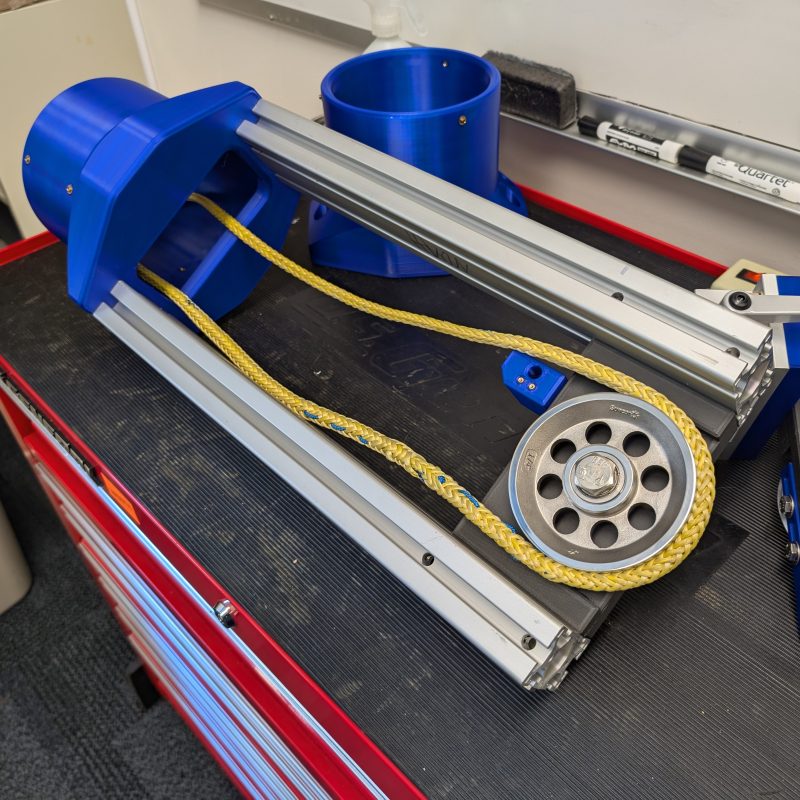

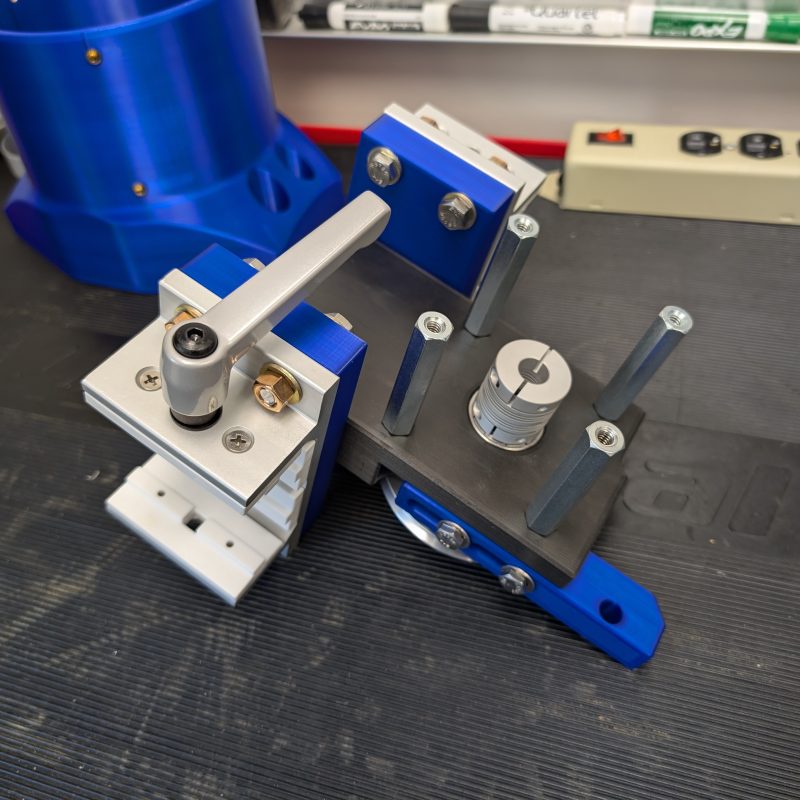

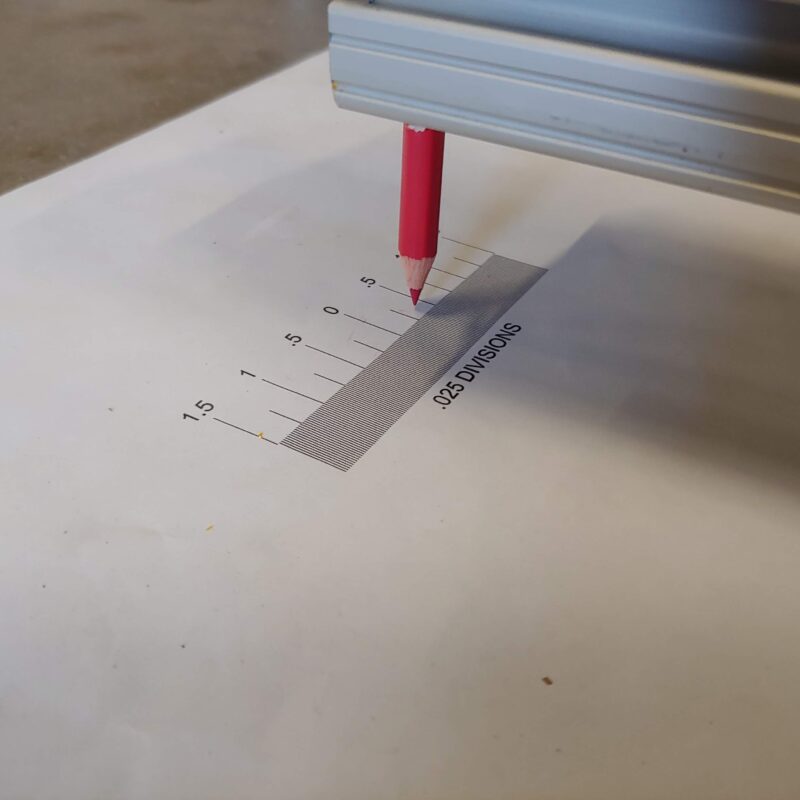

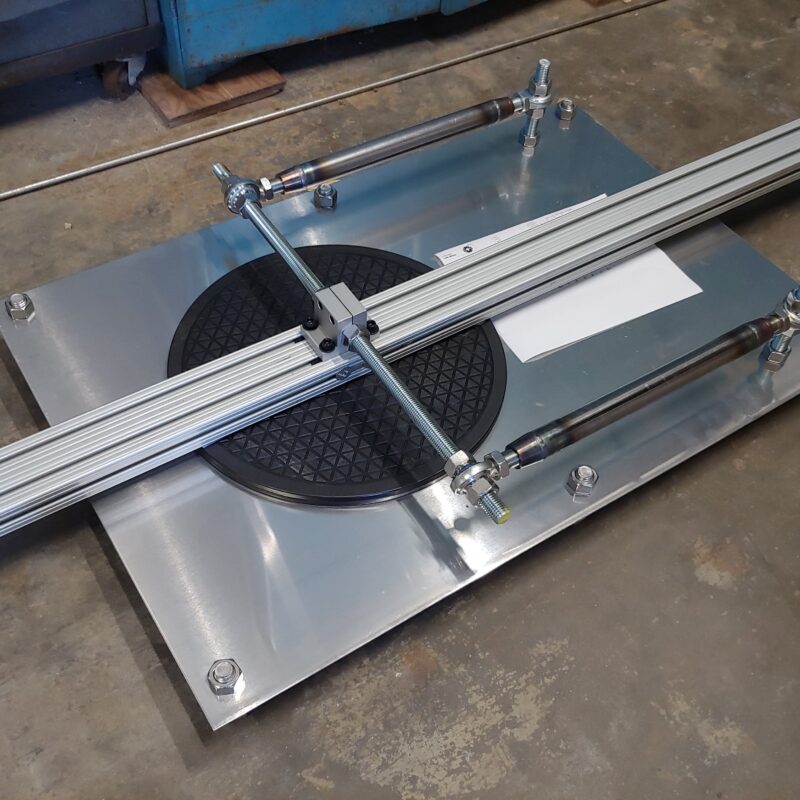

The system I helped design, based on a conceptual system provided by collaborators at Stanford, drives a magnetomer sensor cart suspended by a cable through the 20 foot beamtubes the experiment is built from. A stepper motor drives the cart and allows accurate position measurement, while a battery powered magnetometer sensor beams data back as it travels. Cable tension needs to be as high as 750-1000 pounds to keep the cart from sagging too far! With a turnbuckle and a wrench providing tension adjustment it’s easy to overdo it and bend the tube with tension that high. To avoid this, the design incorporates a load cell that measures cable tension. This also makes correcting for cable stretch a breeze.

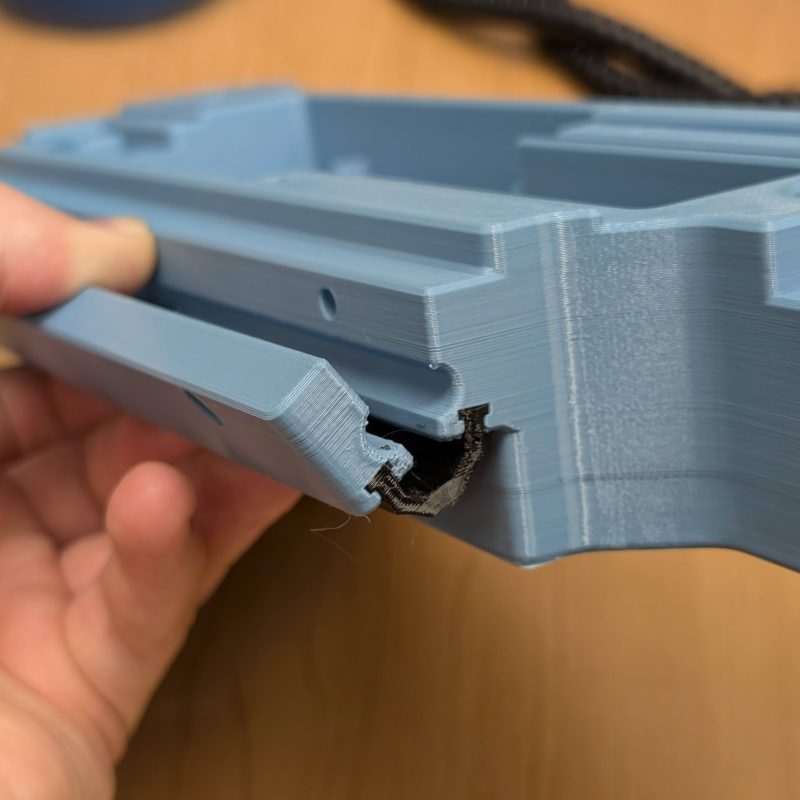

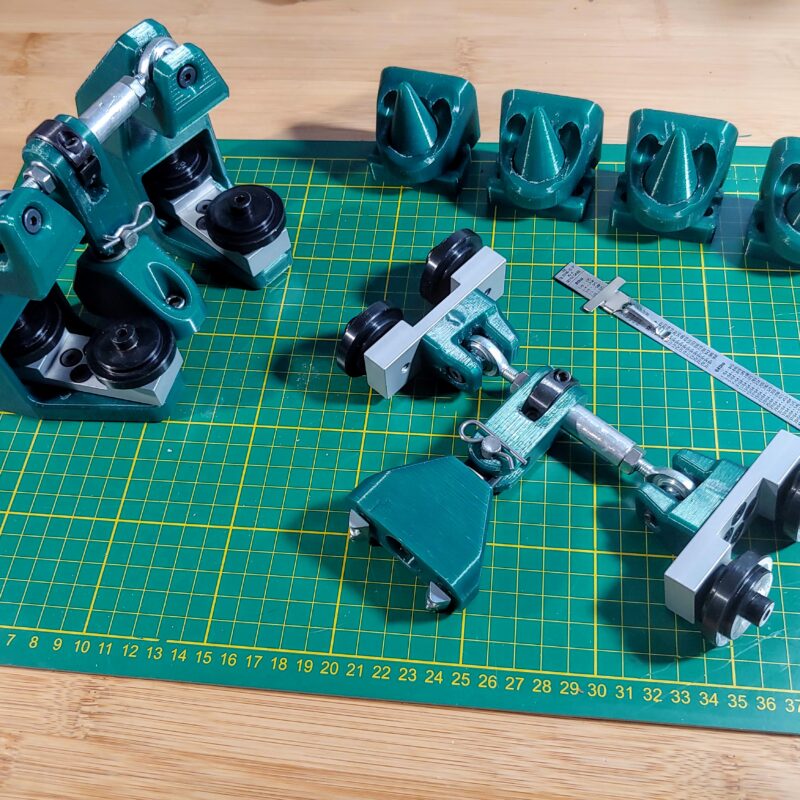

To get the electrical and software teams a functional product as quickly as possible, I 3D printed fiber-reinforced components while we waited for their machined counterparts to come in. The 3D printed cart allowed for rapid changes to the electronics package with new revisions being available to the electrical team within a day or two. The cart takes advantage of multi-material printing to incorporate some built in hinges, as well as some sharp looking labels!