Keeping the strong electromagnets used to steer particles cool is crucial to successful operation of all particle accelerator beamlines. Many magnets at Fermilab are water-cooled using Low-Conductivity Water (LCW), which is water that has been purified to the point such that it no longer conducts electricity. LCW can safely be run through high power magnets or power supplies for cooling without any concern of shorting out the components. At Fermilab LCW is often even delivered to components through thick walled copper pipe called bus that also carries electrical current for the cooled device.

In 2019 I completed the preliminary design for the LCW cooling system for the upcoming Long Baseline Neutrino Facility (LBNF) beamline to provide optimal system performance with minimal cost in accordance with ASME B31.3. In addition to sizing critical components such as pumps, heat exchangers, and overflow tanks based on engineering analysis, I created detailed drawing packages for all parts of the system including instrumentation and valving. I also developed and engineered mechanical supports for wall and ceiling mounted piping runs, and created 3D CAD models for areas where complex pipe routing caused packaging concerns. After the initial design phase I used AFT Fathom hydraulic modeling software to more accurately determine pump size requirements, fluid velocities, and overall system capacity.

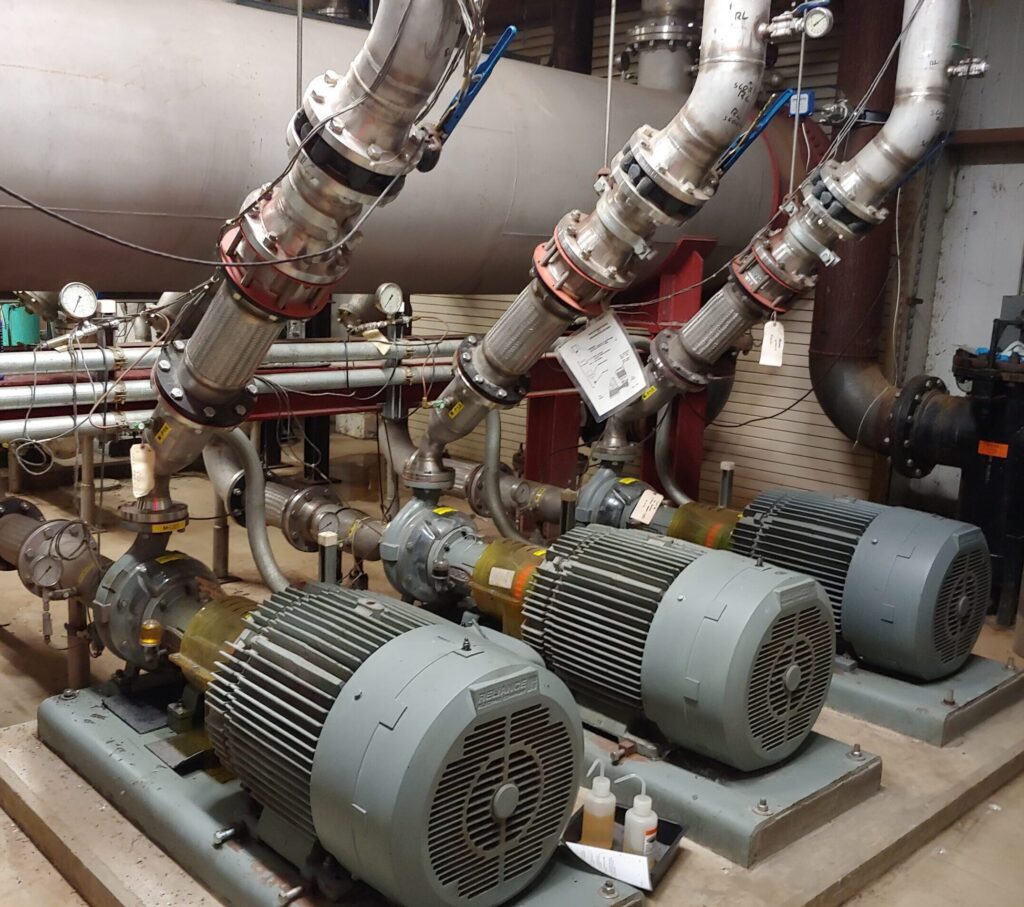

Because the LBNF beamline has not yet been built, I don’t have any pictures of the system yet. Shown above is a picture of the MI-60 pump room at Fermilab displaying three pumps and a heat exchanger similar in size to what may be used for the LBNF LCW system.