Carrying and maintaining enough drone batteries to make it through a full race requires both a significant financial investment and takes up a lot of time. In many ways it’s more efficient to only bring half the number of flight packs you need to make it through a race day, and one larger, lower performance battery that can recharge your flight packs. Commercial, large LiPo batteries for this purpose are available, but I wanted a single battery larger than you could buy. A hard cased battery appealed to me from a durability standpoint, and I had already started dreaming up a 3D printed case. I also only had one very specifically shaped space left in my drone bag that commercial batteries wouldn’t fit in. After deceiving myself into believing that it would probably be cheaper than buying a commercial pack anyway, I set out to build my own battery pack.

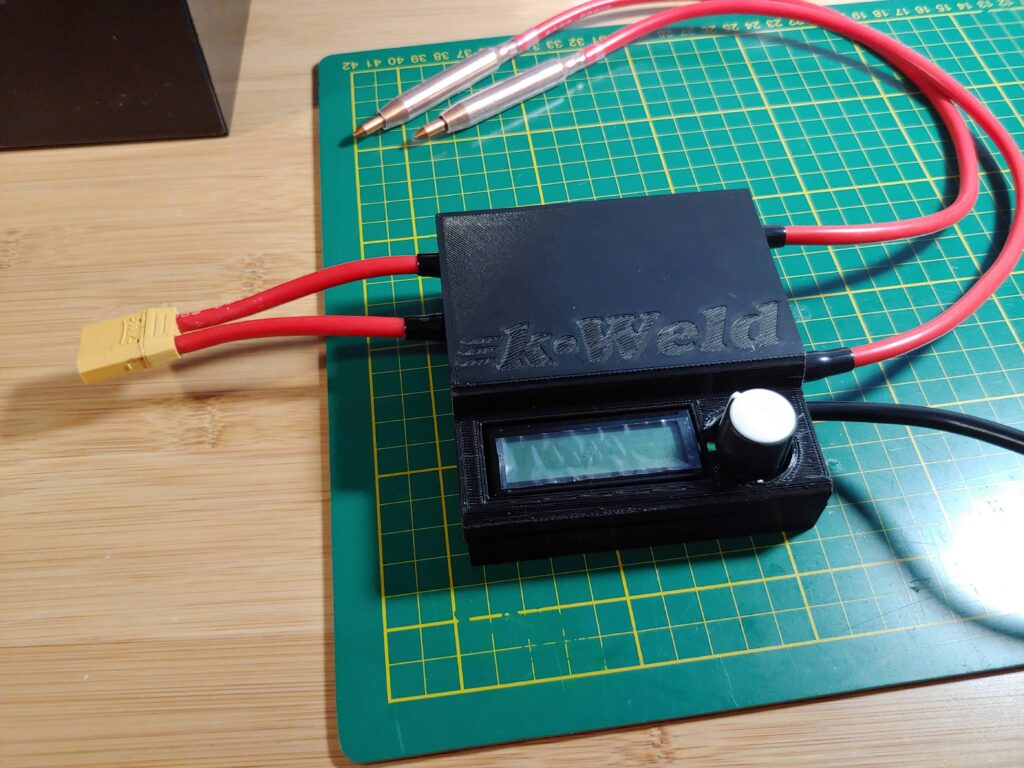

fter attempting to use a co-worker’s battery spot welder and not having much luck, I purchased a K-Weld putting the project way over budget and set to building a battery pack. I used 36 3500mAh Samsung INR18650-35E 18650 battery cells with six cells in each parallel group. To create a good, high-current connection for the power lead, 12 AWG wire is soldered along the full length of the nickel strip on each side. 20 AWG wires are connected to each of the parallel connection nickel strips to act as balance leads. All soldering was performed prior to spot welding the strips on to prevent any damage to the cells. For safety all cells have fish paper caps, each parallel set of cells is wrapped in fish paper, and the pack was wrapped with kapton tape on all sides before being installed into the 3D printed enclosure.

Rather than using a Battery Management System (BMS), I opted to just balance charge the battery with a normal LiPo charger to cut down on the pack size and complexity. Instead of having my power and balance connectors on leads, I installed bulkhead connectors into the 3D printed case. After building the pack, I checked the internal resistance and found the values for each parallel group to be well within the expected range of values. After a full summer of use the battery is still performing great, and will hopefully last for many racing seasons to come.