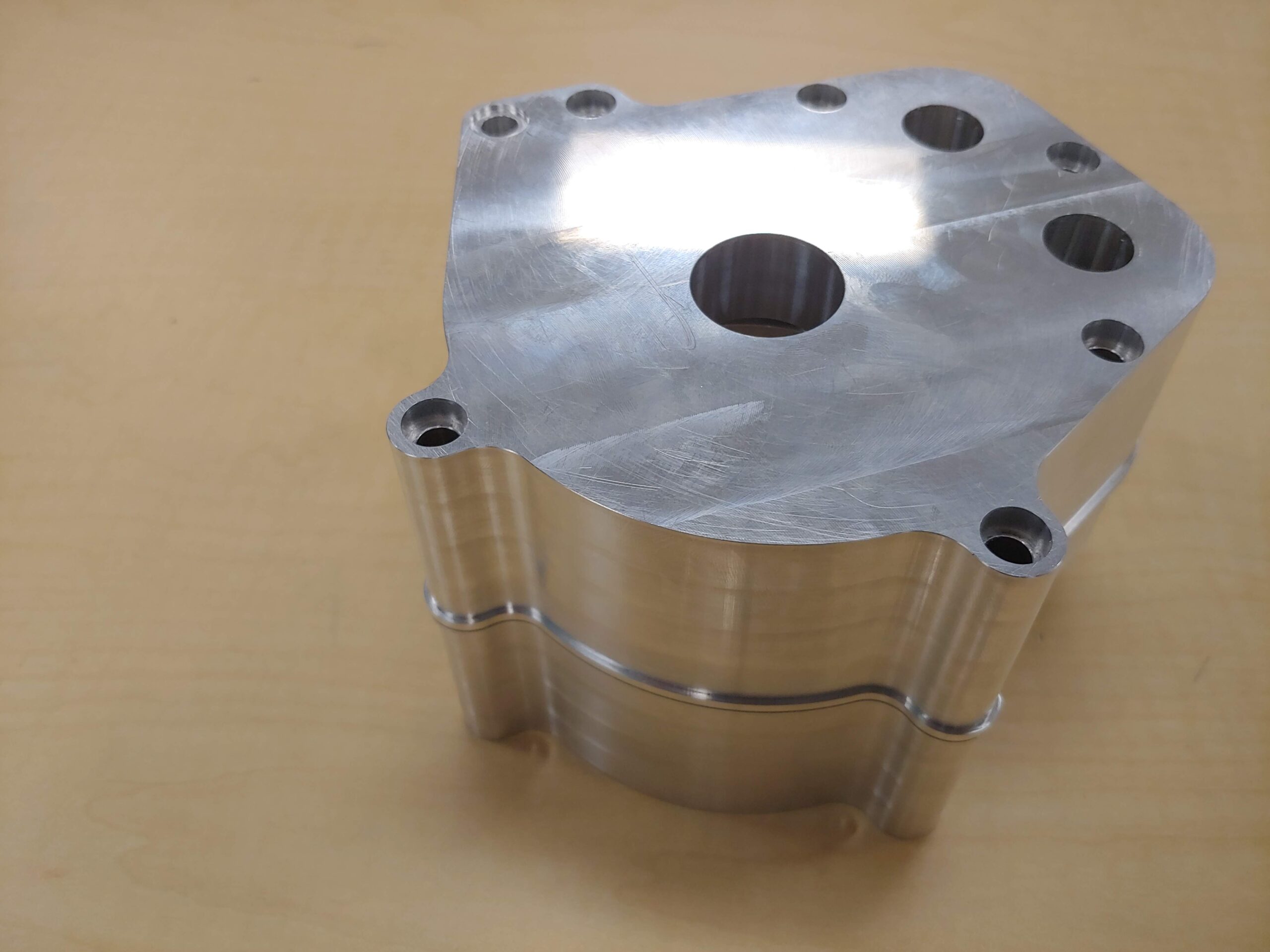

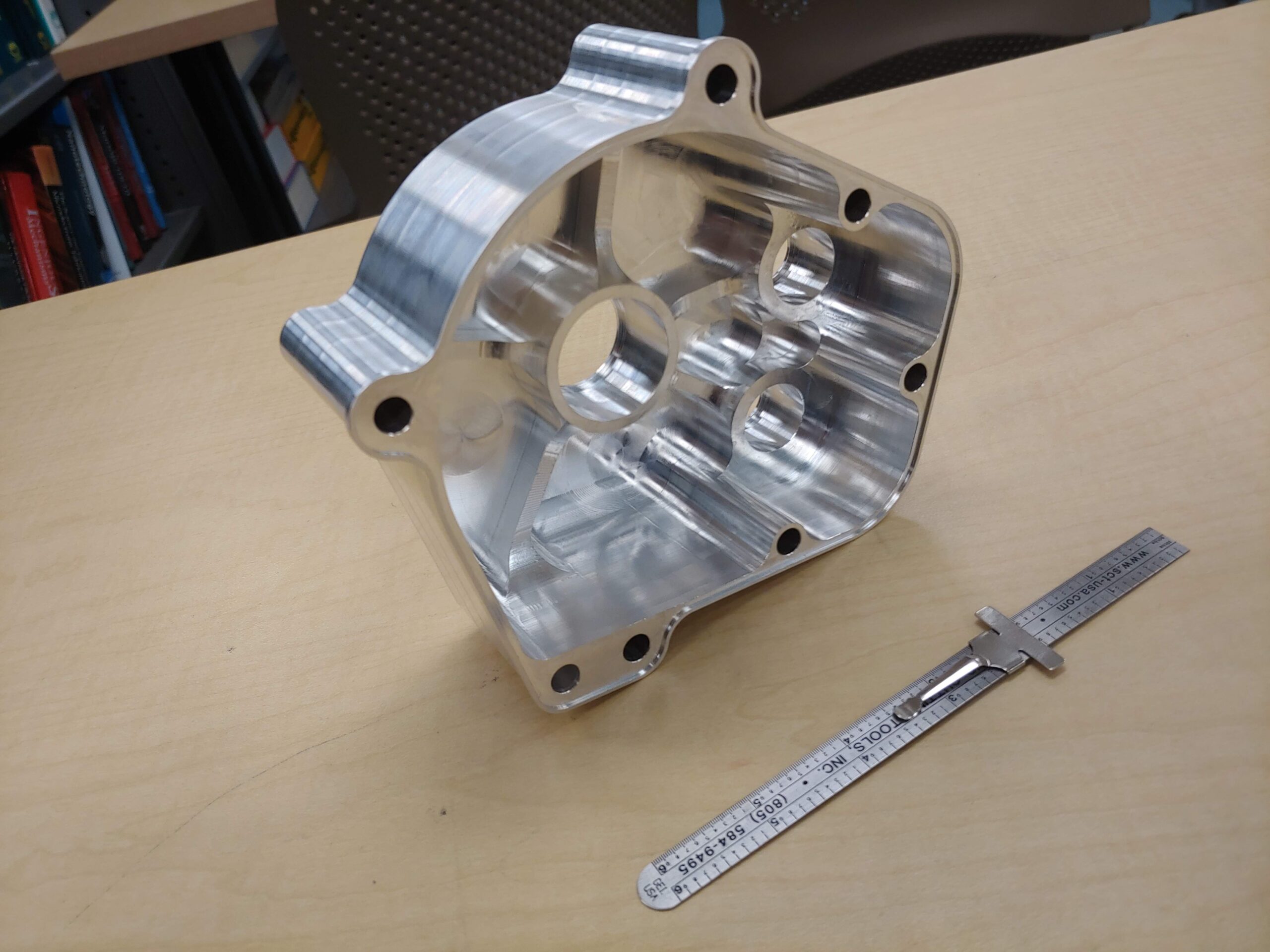

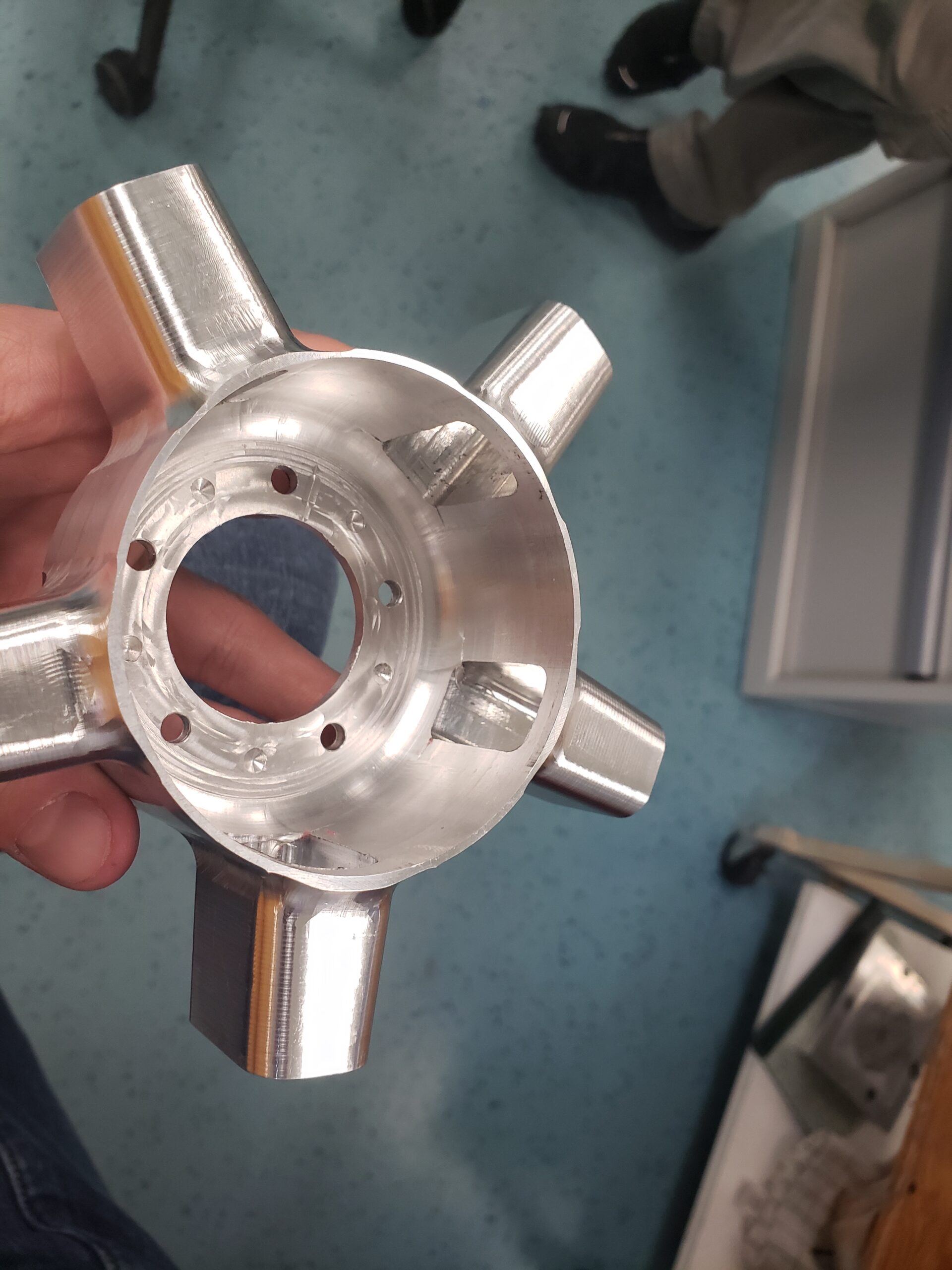

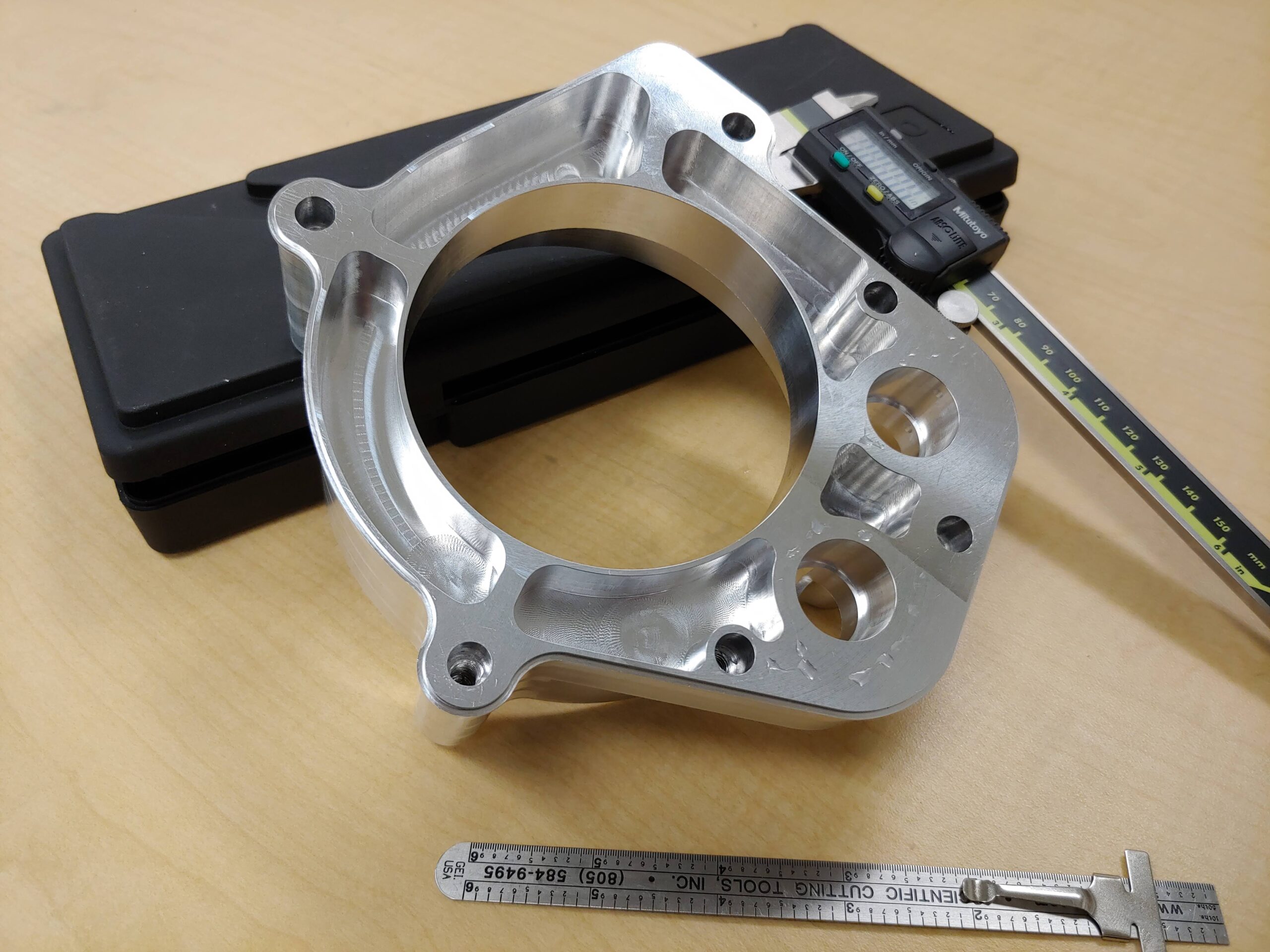

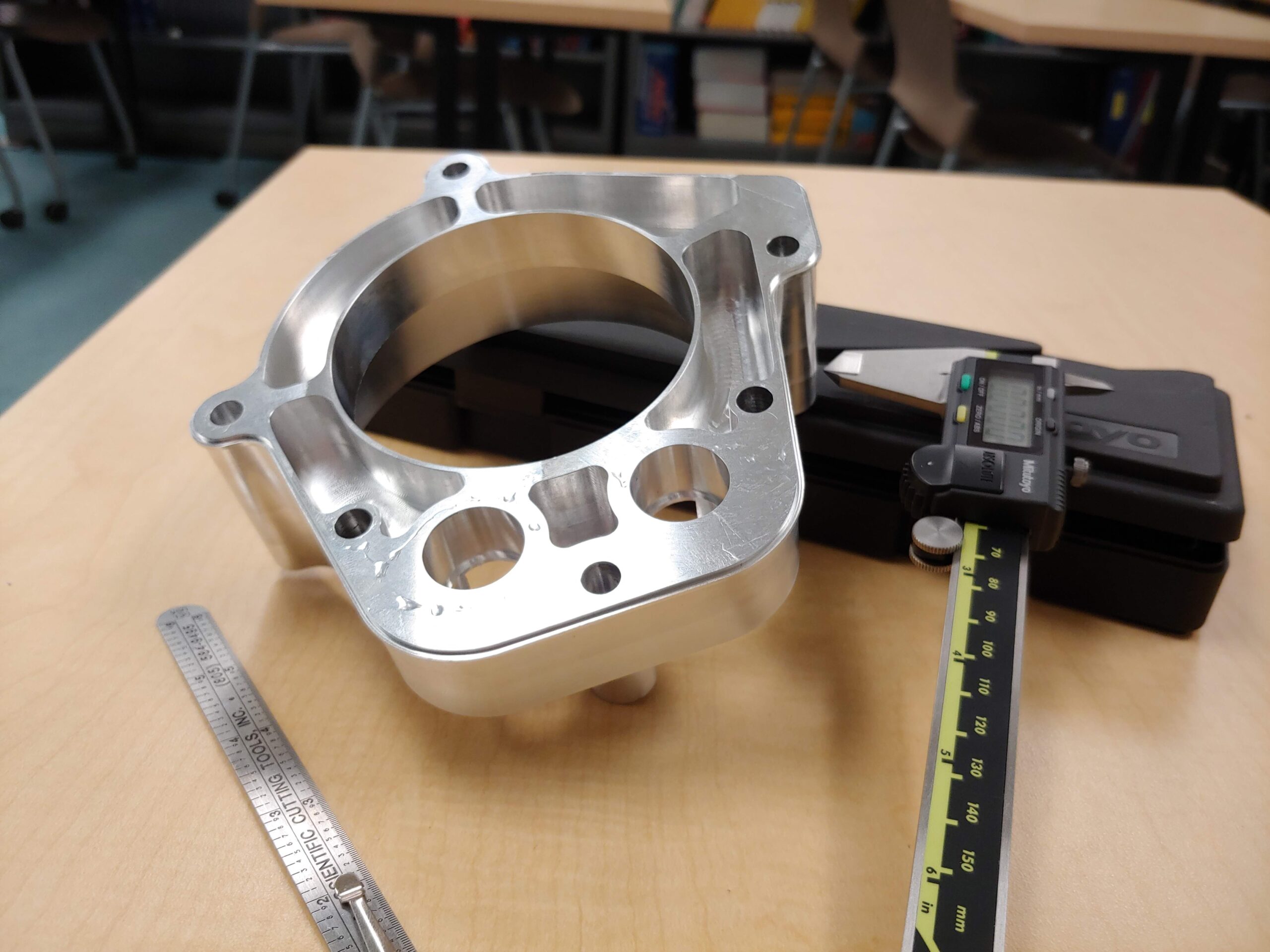

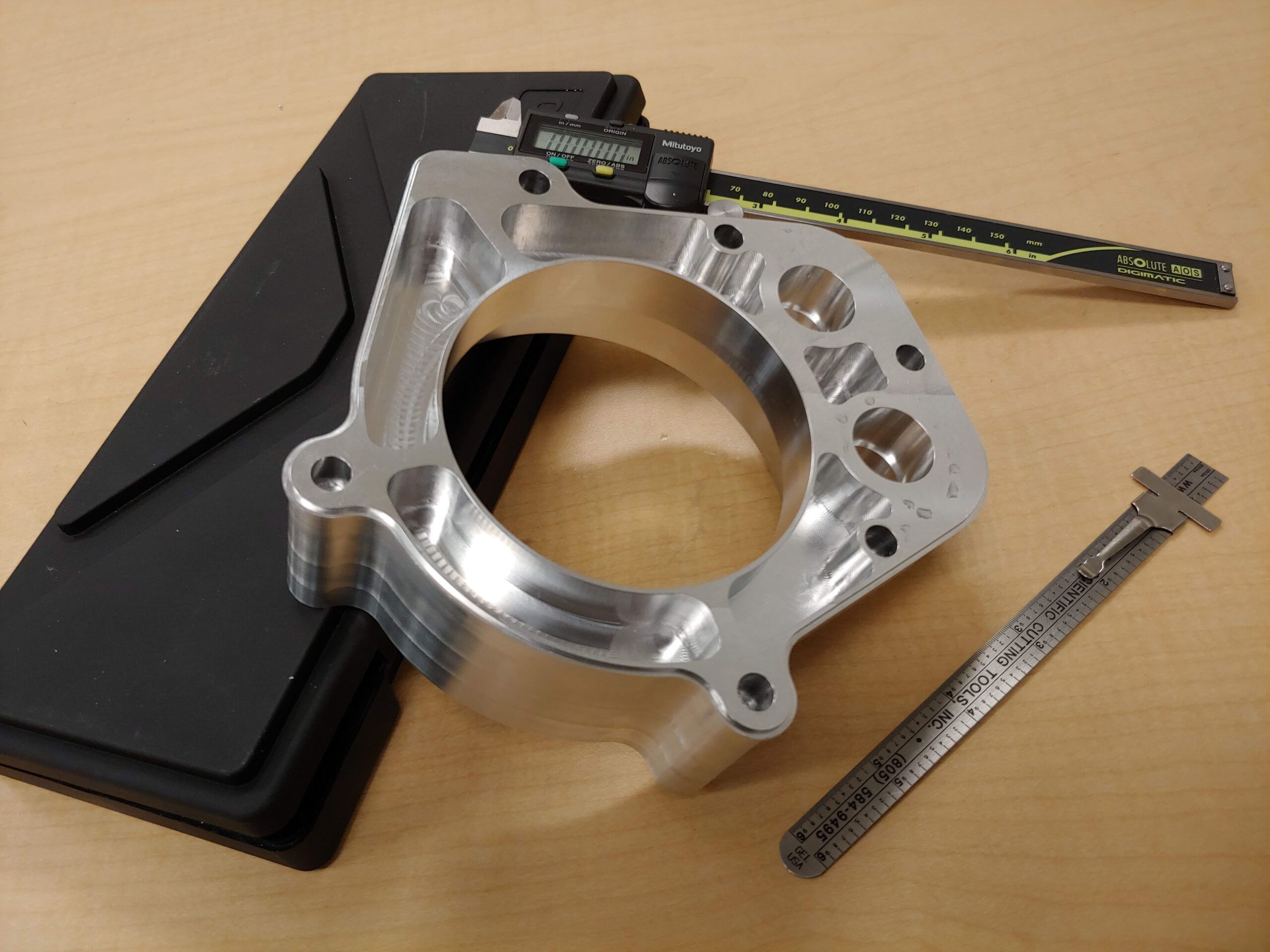

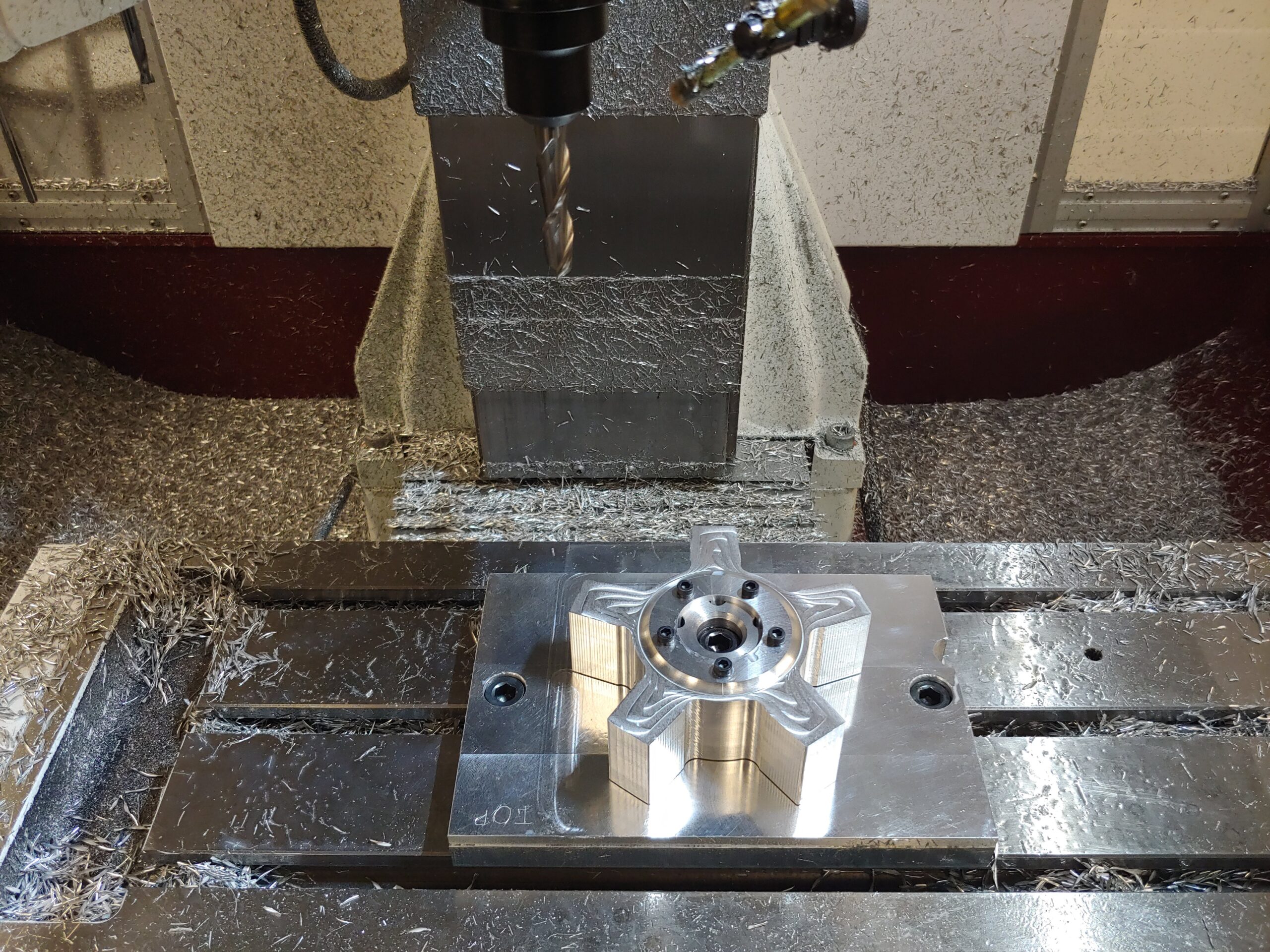

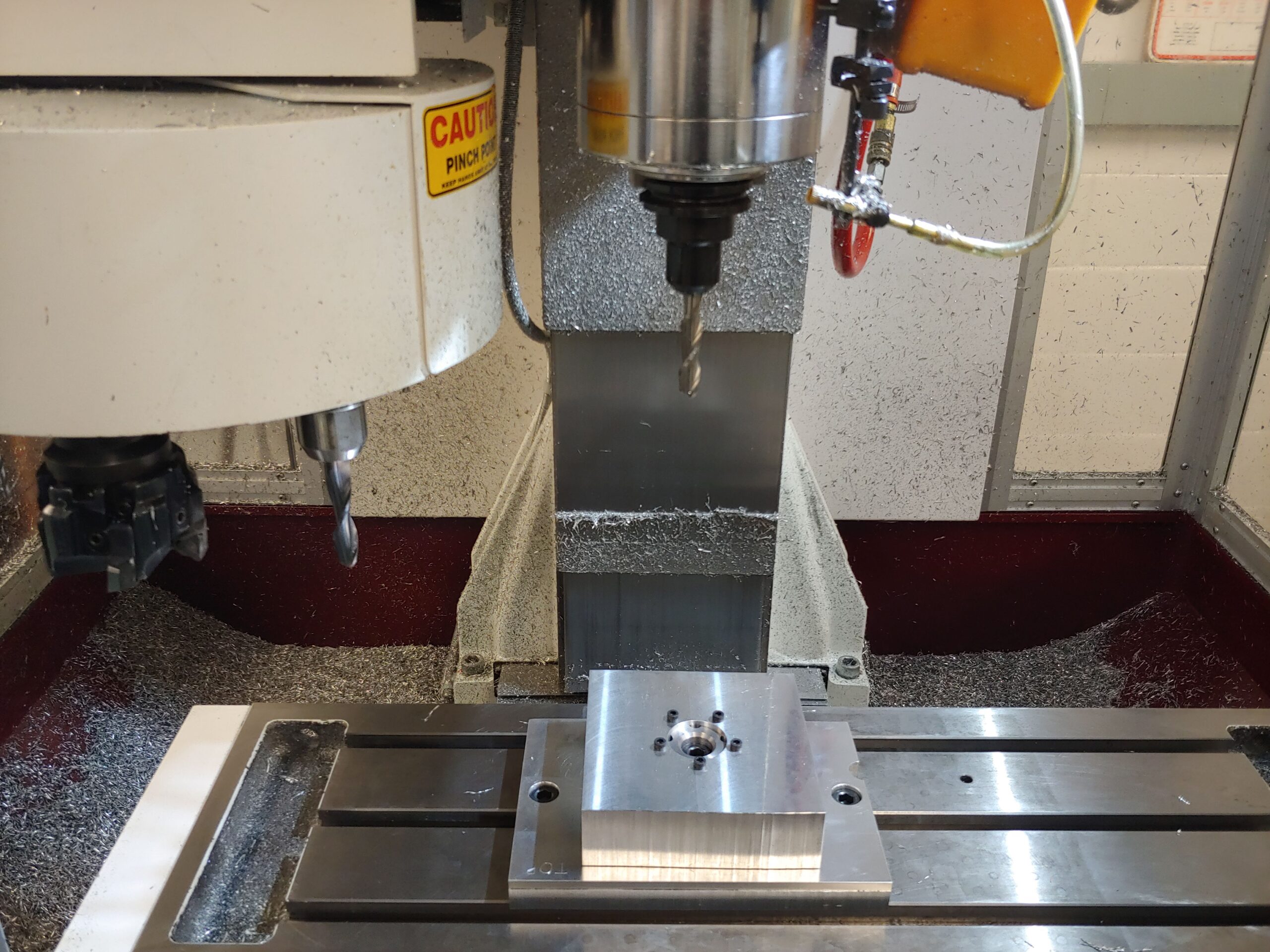

My final year of competing the NASA Robotic Mining Competition was bittersweet. The new robot design was an exciting and huge improvement from previous year’s robots, but due to graduation I was only around for half of the design and build cycle. During the 2019 design cycle I handed off the project lead duties to other team members, and focused on challenging manufacturing tasks and training other team members on how to use NDSU’s CNC equipment. With several other team members on the project, I also worked to develop carbon fiber wheels and a carbon fiber backhoe boom as my senior design project to further reduce the weight of the robot from previous years. The robot used a high torque brushless motor with a harmonic drive gearbox coupled to linkages to drive multiple robot systems from a single motor to reduce weight. The machined components for our custom gearboxes and lightweight wheels were more complex than any parts I had machined before, and required challenging fixture design and CAM programming to successfully manufacture.

After I graduated some modifications were made to the carbon fiber wheels and gearbox systems for improved robot reliability, but in testing the robot performed fantastically. While I wasn’t able to attend the 2019 competition after graduating, I cheered my teammates on from afar while watching the competition livestream as they took home 2nd place in On-Site Mining, 2nd place in Autonomy, and the Innovation Award for the second year in a row.